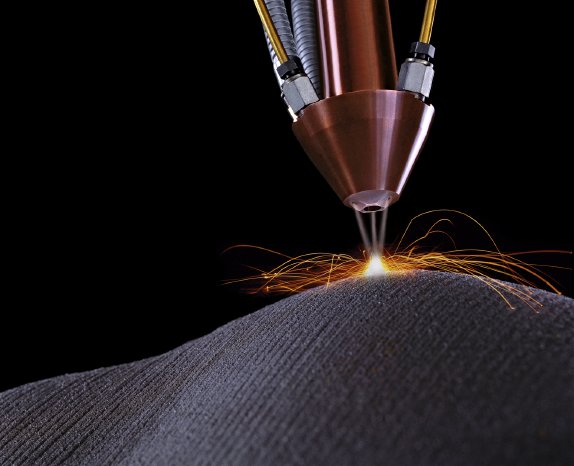

Laser deposition welding as a hard-wearing, reliable solution

Laser deposition welding involves the use of a laser beam to create a molten pool on the component surface, into which a filler material is continually added and melted. Substrate and filler material are combined, producing a melt-metallurgical connection between the layer and the carrier component. Overlapping multiple tracks gives rise to a dense, even layer with defined properties. Compared with conventional techniques, the laser offers several advantages during deposition welding: it only works in the direct vicinity of the weld location. Only a few millimeters away, the rest of the workpiece remains virtually cold. This means intricate shapes can be deposited without any penetration or distortion. The laser can also reach places that are difficult to access, such as internal edges or deep holes.

Protection for deep-drawing tool subject to extreme stresses

Two applications for laser deposition welding can be seen at the EMO. A deep-drawing tool used in automotive manufacturing shows how effectively laser deposition welding can protect surfaces against wear and tear. This heavy-duty tool is used for hot-forming and press-hardening elements such as the B-pillars on bodyshells. In the case of press-hardening, the components need to be quenched; this is done by cooling the tool. The more efficient the cooling, the shorter the cycle time. With this deep-drawing tool, pipes are integrated in globular gray cast iron. The advantage is that the pipes can be routed close to the tool surface. The disadvantage is that the cast iron is very soft. Hence the tool needs to be armored with a hard wear layer.

Following forming, the components are so hard that they substantially improve the safety of the passenger cell. The hard deposition-welded protective layer ensures long tool life. This cooling technique reduces the cycle time of a component by up to 35 percent.

Extended lifecycle for turbines

A repair-welded turbine blade made of titanium demonstrates that laser machining can contribute substantially to extending the lifecycle of components. Components such as compressor and turbine blades are subjected to wear and must be replaced at regular intervals. A targeted, specific repair using deposition welding reliably repairs the components, obviating the need to remanufacture these complex components as part of a time-consuming, resource-intensive process. Cost savings of up to 75 percent can be achieved compared with manufacturing new parts, and the resulting CO2 emissions are much lower. At the end of this process, the surface properties of the repaired turbines are identical to those of a new part.

TruLaser Tube delivers flexible, cost-effective solution

Laser-compatible design is often the key factor in substantially reducing the time, raw materials and costs involved in manufacture. TRUMPF will be demonstrating such design features at the EMO on the basis of a tubular folding bed: the tubes are designed in such a way that they can be formed and welded with minimal effort. Using a laser for tubular designs enables new designs to be created. For instance, specific recesses in the corners for bent edge joints help produce rounded corners in a rectangular tube, thus simplifying subsequent manufacturing stages. The forces for the subsequent bending are kept low and the weld joints reduced to a minimum. A laser tube cutting machine is used to add these recesses quickly and, more importantly, automatically. And since it operates without contact, the laser also produces no distortions in cutting out the keyhole-shaped holes to attach the supporting fabric.

High-tech for the tubes on a folding bed

The folding bed exhibited at the EMO is cut on an automated production line on a TruLaser Tube, automatically picked up by a robot, and then transferred to the next manufacturing cell: a bending and welding station. The laser machine determines the speed for the rest of the plant. Using a configurable digital interface, it notifies the other control units in the production cell when a part is ready. The major challenge in setting up this automated plant was to guarantee the exact positioning of workpieces for the next station. The right positioning of the cut tubes on the x and y-axis was ensured by programming the TruLaser Tube: the rotary unit on the machine tool aligns the machined component precisely at the angle required for the downstream process before the component is cut away. Positioning along the z-axis is achieved by means of a purpose-built support table which replaces the normal transport table. Driven by a servomotor, it moves the components precisely into the position required in each case. The robot picks up the machined tubes and places them into the bending and welding station with millimeter accuracy. This allows the robot cell to produce 240 frames daily, with a folding bed coming off the production line every 2 minutes.

TRUMPF at EMO, Hanover, September 19 to 24 2011 / Hall 12, booth C72