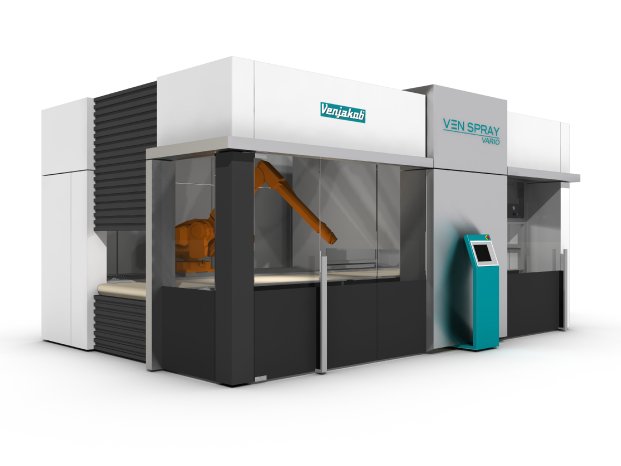

For the first time in this branch, Venjakob has combined an antromophical robot with a linear spray coating machine. The VEN SPRAY VARIO combines the flexibility of an industrial painting robot with the high output of a reciprocating spraying machine. Precise coating of edges by robot and coating of surfaces by reciprocator with constant speed "inline"; no stopping, no stop and go, just constant work flow. Therefore more output (coated surface/minute) in comparison to other machines, available on the market.

One advantage of this system technology is also the better cross linking of the paint film at the transition from the surface to the edges.

Complex 3-D parts can be coated while stationary. In this case the usage of the optional paper belt transport system is recommended. For further flexibility, the plant can also be operated only in surface modus.

As an Alliance Member of "Blue Competence ", an initiative of the VDMA, Venjakob has focused on energy and resources efficiency while developing new plant technologies.

An example is - among others - a well-engineered and effective paint-recovery system. In addition, efficient fan technology reduces the energy consumption. The modular design pays back to the customer and his permanently changing requirements. As the need arises, the plant concept can be expanded variably e.g. one robot with linear axis or two robots followed by a linear axis for a higher output.

Constant parameters, equal exhaust and drying times of the work pieces guarantee reproducible results and best finishing quality.

Besides new developments from the company finishing sector, Venjakob has focused its research and development activities also on enhancements in UV curing technology. Appropriate to LIGNA, everything centers on the topic LED-UV. Interested visitors may view an LED module with an effective width of 1300 mm at the booth. The new VEN DRY UV-LED is designed for the curing of lacquer on three dimensional work pieces. Thereby the advantages of LED-technology are now available in the area of 3D-curing. The main advantages of this new technology are the reduction of energy consumption and the low thermal impact of the work pieces.

Further aspects are the remarkable higher economic life-time of the lamps as well as the omission of the genesis of ozone compared with conventional UV technology. Therefore there is no demand for a continuous exhaust air, which has a positive influence on the energy balance for the air in the building. The necessary cooling is achieved by a small water radiator. The characteristic of the LED enables width control of the lamps with a piece related switching on and off of the individual LED segments.

The LED-UV-technology is therefore a consequent step towards a gentle and energy saving curing of lacquer surfaces.