Always with its finger on the pulse of time, ViscoTec’s own brand is specialised in micro-dosing. Thanks to its extensive range of one and two component dispensers, it delivers the highest quality tools for the high-end products of today and tomorrow. With the eco-DUO450 and the eco-DUO600, preeflow have already successfully covered the market of 2 component dispensers with dosages of 0.2 to 32 ml/min. However, preeflow have now mastered the next challenge in the area of 2 component precision volumetric dosing. And it is presented these days in Stuttgart at Bondexpo - Vieweg booth 9202

Revolution through evolution - the eco-DUO330

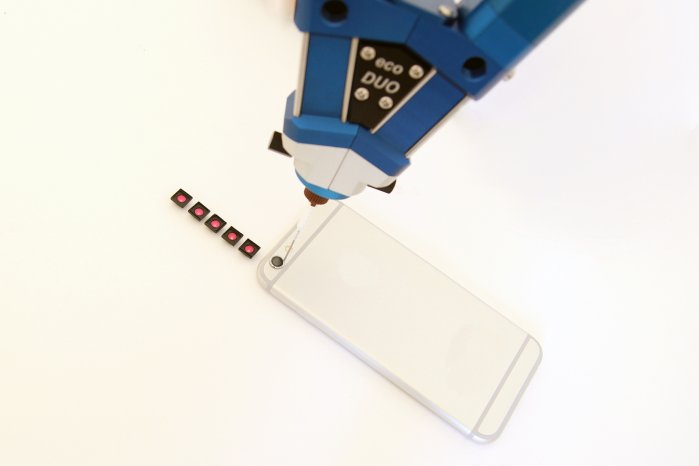

The less the amount of material to be mixed, the greater the challenge for the dosing system: Due to the World’s increasing miniaturisation in areas such as electronics and the associated high demand for ever smaller and more precise dosing, preeflow has developed the eco-DUO330. This system provides the answer to numerous questions from application engineers, material manufacturers, plant engineers and product developers. Be it in medical technology, optics and photonics, the manufacture of electronic components or in the field of biochemistry and the production of semi-conductors: Miniaturisation does not ever seem to stop in any of these markets, making these the perfect fields of application for the eco-DUO330.

The eco-DUO330 is the further development of the successful eco-DUO450 and represents a masterpiece of workmanship “made in Germany”. Precision mechanics, coupled with a state of the art digital control unit sets new standards in the field of dosing and repeatability in very small quantities and closes a gap in the requirements for small volume dosages in the area of 2 component systems.

eco-DUO330 – pushing its limits to the extreme

Adherence to the exact mixing ratios of the 2 component materials and its precise coverage can greatly influence the processes and applications from time to time. Even small deviations can negatively affect the desired results. Compounds harden only partially, adhesive bonds do not reach their load limit and, in the worst case, chemical reactions from the materials could have an unforeseeable impact on the user.

Preeflow prevents all these risks from happening: As in all of the manufacturer’s dosing systems, the new precision-volume mixing head is built using the proven endless piston principle, working as a rotating, completely pressure-tight positive displacement system. This is best suited for the promotion, dosage and application of low, medium and high viscosity liquids. Pulsation-free dosing takes place and the shear forces exerted on the medium are reduced to a minimum.

eco-DUO330 dosing to the limit

With the newly developed eco-DUO330, dosing quantities of 0.005 ml (per shot) is achievable. Irrespective of temperature, time, pressure and viscosity – dosed as a dot or bead. Therefore, the smallest quantities can be created at that very moment. The microprocessor-controlled system creates a dosing accuracy of ± 1 % and repeatability of over 99 %. And this whole process is absolutely reliable and reproducible. Specific to the application, the mixture ratio can be easily adjusted from 1:1 to 10:1 using the intelligent control via the graphical interface. The dosing of dots, as well as bead applications, can be subjected to a continuous quality check thanks to the integrated pressure monitoring. The continuous bead application is at a maximum 6.6 ml/min, whereas a variable bead thickness from 0.1 mm to approximately 2 mm (directly proportional to the speed of the application) has not been achievable until now.

In combination with the proprietary, high-quality precision manufacturing of rotor and stator, the eco-DUO330 is a guarantee for the best dosing results and consistent application processes. With these benefits it opens up numerous, new and unrivalled areas of application in micro dosing. Push your limits and go all the way with the eco-DUO330. More information available at www.preeflow.com