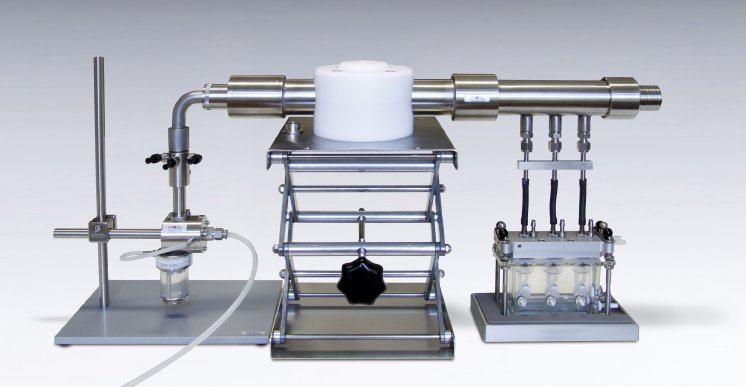

VITROCELL® presented on both events a turnkey in vitro exposure system for applications where the test substance must be dosed in smallest quantities. The system is based on an aerosol generator which was specially developed for this purpose.

It works at low flows at e.g. 2-6 liters/min. and has a low dead space. It can be operated in 2 modes:

• recirculated flow mode using a small reservoir (standard size 15 ml). The air flow rate is chosen by the user based on the desired aerosol concentration to be delivered

• direct feed single pass mode where the test substance is dosed by a precision pump (e. g. peristaltic pump). This permits adjustment of the aerosol concentration without altering the air flow rate.

The nebulizing generator is made of stainless steel and is easy to clean.

The generator is connected via a special setup to the VITROCELL® cultivation and exposure modules. The optional drying system dries the aerosol so that the test substance can be submitted in dried state to the exposure modules.

About the VITROCELL® cell cultivation and exposure technology for gases, complex mixtures and nano particles

The direct exposure of the cells takes place at the air liquid interface in the VITROCELL® cell cultivation and exposure modules. For this purpose, the cells are first cultivated on membrane inserts (e. g. ThinCerts® from Greiner, Costar® from Corning or Falcon® from Becton Dickenson). The membrane inserts are placed in the modules which are tempered at 37°C. The medium supply is performed either statically or by permanent exchange. In both cases the cells receive the cell culture medium from below through the membrane of the insert.

In the direct exposure technology, the test atmosphere is delivered to the cells via specially treated aerosol inlets using a low vacuum flow. As the cells are not covered with medium, they are exposed most efficiently at the air liquid interface and can therefore react in an optimal manner. After exposure, the membrane inserts are taken out of the module and cells are forwarded to standard routines for endpoint analysis.

The VITROCELL® product range helps to reduce animal testing in the field of e. g. inhalation toxicology. For this purpose human cells are cultivated in special exposure modules on membranes and then exposed at the air/liquid interface to the test substances. The same technology can also be applied to bacteria.

The customers of VITROCELL® Systems GmbH are leading research institutes, contract research organisations, regulatory authorities as well as the pharmaceutical and other industries throughout the world.

More information:

www. vitrocell.com