This special sensor can now also be integrated in the VITROCELL® 12 stainless steel exposure module. Together with the VITROCELL® 6 PT-CF stainless steel exposure module there are now dose control solutions available for the work with 12-well and 6-well sized cell culture inserts.

Turn-key installations for the analysis of aerosols from dry powders, liquids and suspensions

In using VITROCELL® technology, the aerosol can be generated from non-cohesive, dry powders and dusts down to the size of nano particles. The other option is to generate the aerosol from liquids, solutions and suspensions. In this case a dry aerosol can be obtained by a special aerosol generator with an integrated drying unit. The aerosol generator can be directly connected to the VITROCELL® cell cultivation and exposure modules.

Turn-key installations for the analysis of gases and complex mixtures

The analysis of gases, volatile organic compounds (VOC) and complex mixtures from combustion processes such as cigarette smoke or Diesel exhaust is performed with special configurations.

About the VITROCELL® cell cultivation and exposure technology

The direct exposure of the cells takes place at the air liquid interface in the VITROCELL® cell cultivation and exposure modules. For this purpose, the cells are first cultivated on membrane inserts (e. g. ThinCerts® from Greiner, Costar® from Corning or Falcon® from Becton Dickenson). The membrane inserts are placed in the modules which are tempered at 37°C. The medium supply is performed either statically or by permanent exchange. In both cases the cells receive the cell culture medium from below through the membrane of the insert.

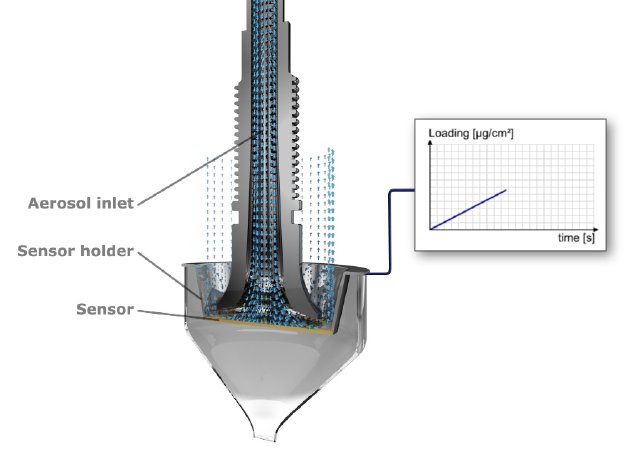

In the direct exposure technology, the test atmosphere is delivered to the cells via specially treated aerosol inlets using a low vacuum flow. As the cells are not covered with medium, they are exposed most efficiently at the air liquid interface and can therefore react in an optimal manner. After exposure, the membrane inserts are taken out of the module and cells are forwarded to standard routines for endpoint analysis.

The VITROCELL® product range helps to reduce animal testing in the field of e. g. inhalation toxicology. For this purpose human cells are cultivated in special exposure modules on membranes and then exposed at the air/liquid interface to the test substances. The same technology can also be applied to bacteria.

The customers of VITROCELL® are leading medical and environmental research institutes as well as the pharmaceutical and other industries.

More information:

www. vitrocell.com

info@vitrocell.com