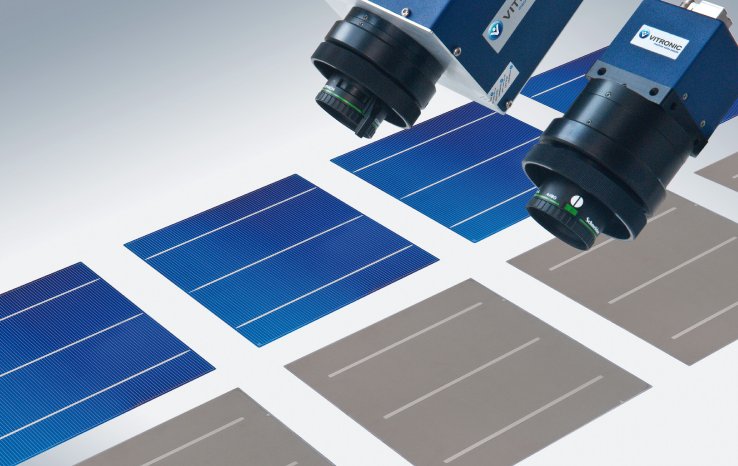

VINSPEC SOLAR inspection systems allow automated optical quality inspection without manual checking – even for production capacities in the gigawatt range and high production throughputs. This is based on the combination of hardware and software to form integrated solutions which provide optical inspection at every relevant production step. Optical inspection using machine vision guarantees coating and printing processes at the highest level of quality. Solar cells can be checked on the front and back for color, print, surface and geometry to ensure the highest quality and sorted for further processing, for example by quality and color classes. In module production, the systems also allow a high level of automation; electroluminescence makes even invisible differences in quality visible so that they can be evaluated.

Modular structure for individual solutions: The software of the VINSPEC SOLAR inspection systems has a modular structure and uses a separate module for each step in the inspection process. If a new busbar shape changes the cell layout, for example, only a single software module needs to be replaced, while the rest of the software remains unchanged. Even if the manufacturer wants to integrate new inspection criteria, such as contour inspection, there is no need to replace the entire software. All it takes is the installation of a new module. This ensures the greatest possible flexibility and low costs in new inspection requirements. Moreover it increases process reliability and guarantees stability in all inspections.

The hardware consists of linescan or matrix cameras, illumination and application-specific evaluation. Because a production line can contain over a hundred inspection systems, each of the interlinked systems can be monitored from any position. All systems are integrated into the factory's MES in order to make it easier to control the plant and archive the data collected as well as use it in optimization processes.

VITRONIC exhibits: Hall 3.0, Booth H5