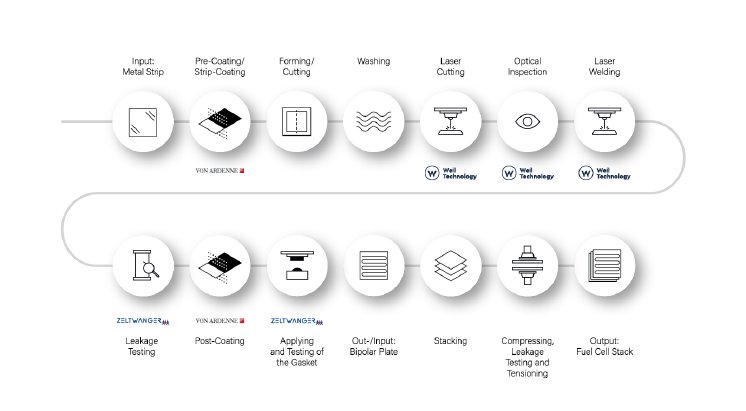

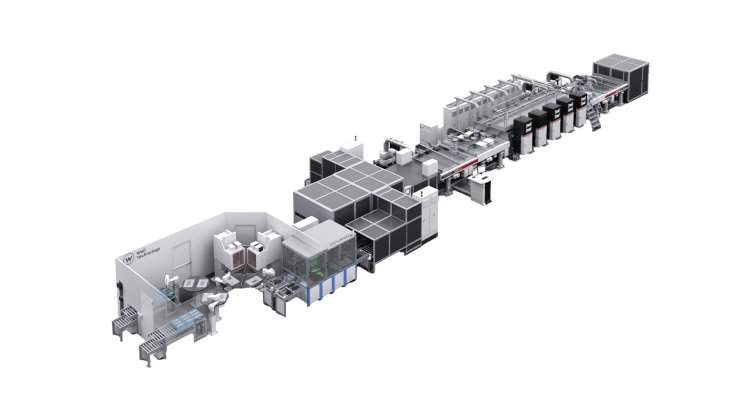

An interface-coordinated complete line for the highly efficient production of metallic bipolar plates is offered by the three companies VON ARDENNE, Weil Technology and ZELTWANGER, which have joined forces as partners in the GERMAN FUEL CELL COOPERATION (GFC).

They will show the advantages and possibilities of their system at Hannover Messe, April 22 - 26, in hall 13, booth D72.

Well positioned for the mobility requirements of tomorrow

Their fully coordinated production line plays a pioneering role in the market: By bundling their respective competences, the three German companies VON ARDENNE (Dresden), Weil Technology (Müllheim) and ZELTWANGER (Tübingen), as partners in the GFC, offer manufacturers of fuel cell and electrolyzer stacks comprehensive know-how in all sub-processes for the efficient production of metallic bipolar plates. With an annual production capacity of several million bipolar plates, it covers the current needs of the industry.

Weil Technology has developed the Laser Welding Cell (LWC), which precisely joins the thin metal foils at high welding speeds. For leak testing, ZELTWANGER brings in the fully automated ZED BPP 4-2 test station in addition to a manual test station, which also achieves very low cycle times. The VON ARDENNE coating system uses cathode sputtering or magnetron sputtering in the post-coating process to coat the bipolar plates directly on both sides. The GFC partners support their customers in the scaling of processes and systems from development on a laboratory scale to pilot production and high-volume production.

Machines are already being built for leading companies in the hydrogen and fuel cell industry. An ideal prerequisite for reducing dependence on fossil fuels quickly and efficiently.

From metal strip to fuel cell or elektrolyzer stack

The long-standing expertise of the three mechanical engineering companies covers all process steps. The joint development and careful coordination of the line concept enables smooth transitions at the interfaces of the individual production steps. For this purpose, the line processes pre-embossed half-plates made of stainless steel or titanium. In a first step, these are welded into bipolar plates, then tested for leak tightness and finally receive a PVD coating to functionalize the surface.

GERMAN FUEL CELL COOPERATION – Booth, dates, contact

April 22 – 26 2024

Hall 13, booth D72, Messe Hannover, Germany

Web: www.fuel-cell-cooperation.com | https://www.hannovermesse.de