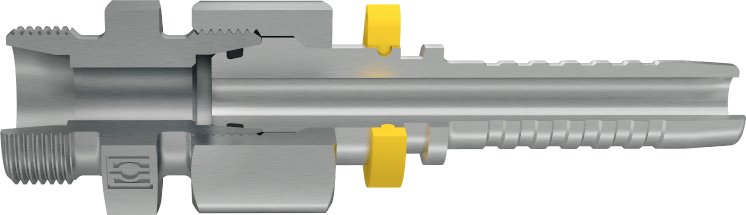

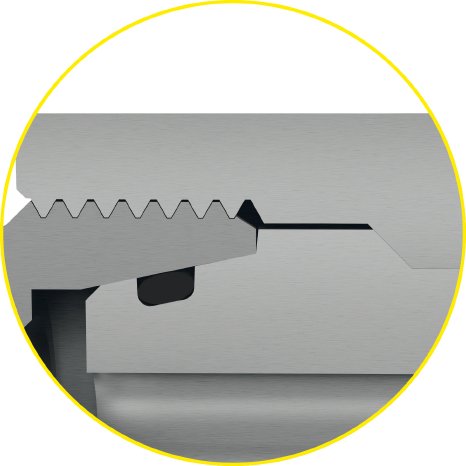

This series has proved its worth since its presentation at bauma 2016. Its special design feature is the block stop. It ensures that during assembly the required pre-tension for a reliable and permanently tight connection in the thread pairing is achieved. This is brought about by a pre-defined gap width between the two faces of the components to be bolted.

It has two immediate positive effects: an excessive tightening, i.e. the permitted tightening torque being exceeded, is safely stopped since the installer effects assembly “en bloc” – hence the block stop name. This considerably reduces the risk of leaks in the sealing area of the connector. At the same time, the pre-tension created in the thread prevents any self-actuating detaching of the connector under load. This significantly raises fail-safeness of the detachable connection and does so permanently. After all, even with multiple connector detaching and re-joining, there is no risk of the metallic sealing faces remaining deformed from excessive tightening and adversely affecting the sealing function. This not only increases leak protection but also the service life of ECOVOS connectors over the conventional, detachable hose connections.

Another great advantage is that the block stop works irrespective of the material pairing. The user does not have to adapt the torque, for example when pairing the hose connector with forged part fittings. This ensures additional leak protection, particularly in mobile hydraulics.

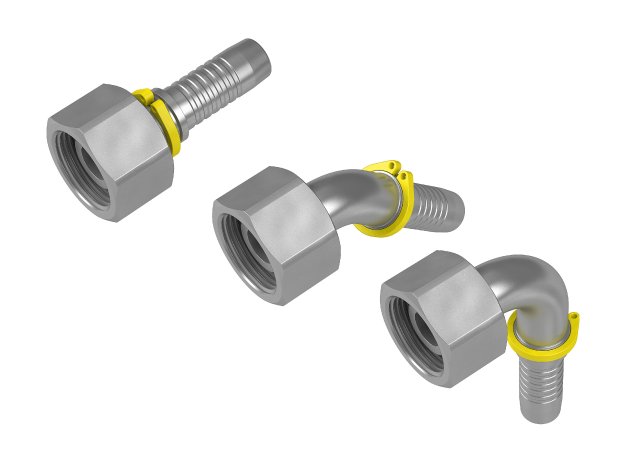

Up to now the ECOVOS hose connectors with 24°sealing cone (EN 8434-1), O-ring and block stop have been available in the DN 06 to DN 16 hose nominal widths. Stauff has now added the DN 19 and DN 25 hose nominal widths to the range. The DN19 hose nominal width corresponds by default to the 22L and 25S-sized sealing cone attachments whilst the DN25 hose nominal width deploys the 28L and 30S-sized sealing cone attachments as standard.

The new hose connectors with block stop are available in the three typical tail directions (straight, 45° and 90°). The reason for extending the range were customer enquiries wanting factory-based final assembly of the system hose lines, uniform assembly sequences for all sizes used and a long-lasting, leakage protected and easy to assemble solution for the sensitive hydraulic component and hose interface.