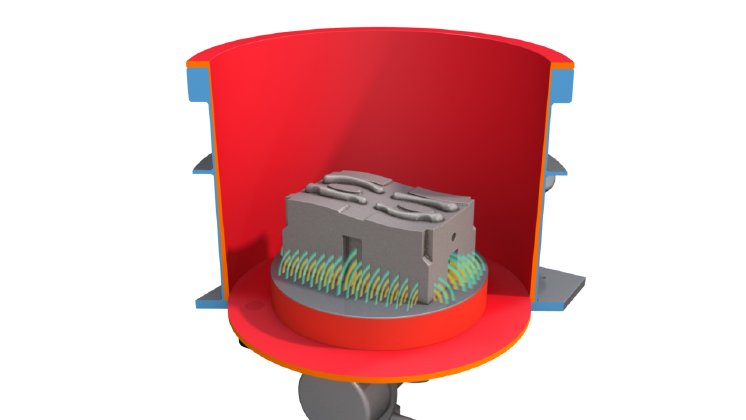

The multivibrator machines of the MV series for fine grinding and polishing feature an integrated magnetic plate which holds the work pieces in place by an electromagnetic field. By this solution, Walther Trowal achieves a high relative speed between the work pieces and the media as the work pieces vibrate at the same high frequency as the work bowl. This intensifies the impact of each individual contact between the media and the surface of the work piece. The result: perfectly clean surfaces and drastically reduced processing times.

A further advantage of the new technology, which is uniquely offered by Walther Trowal, is that the handling effort required for fixing the work pieces inside the container is reduced to virtually zero, as the work pieces are simply placed on the magnetic plate and fixed in place by the electromagnetic field. Moreover, thanks to the magnetic plate it is no longer necessary to develop different clamping devices for different work pieces.

The MV machines are particularly well suited for work pieces of complex shapes, which may include webs or ribs, and for removing extremely sticky dirt.

An example of successful application of this technology is the cleaning of dies for forging rims and transverse rods. In the forging shop, these dies are exposed to very harsh ambient conditions. Scale forms on the surface and they oxidize and contaminate over time. Material adhering to the surface of the die, for example solid scale, leaves undesired marks on the forging, impairing the quality of the forged part and requiring extra reworking. In the past, these dies used to be cleaned by hand. This involved a lot of time and effort. A multivibrator machine can now reduce the average processing time of 8 hours to between 0.5 and 4 hours.

The core elements of the MV machines are the three high-speed eccentric drives which set the work bowl into vibration. These drives are variable in terms of position and direction of rotation. They produce extremely small vibration amplitudes. As the oscillations superimpose in their direction of action, the multivibrator achieves excellent cleaning results, even on complex or sensitive workpieces - and especially in those areas of the work pieces where conventional mass finishing used to have its limitations.

Walther Trowal at AMB 2012 in Stuttgart, Germany (September 18 – 22, 2012): North Hall, stand N-6762