At “Husum Wind 2017” Weidmüller will be presenting customised solutions for wind power installations, including digitisation and industrial analytics systems for condition monitoring as well as sub-applications in wind power installations. These products will be supplemented by complete automation solutions for small wind turbines. As long-standing and successful partners of the wind power industry, the specialists of the “Weidmüller Wind Team” have broad expertise and a thorough understanding of customer applications. Our experts will be available on all days of the exhibition to engage in intensive dialogue with customers.

Digitisation and industrial analytics

Digitisation solutions such as industrial analytics are increasingly finding their way into the wind power industry. Weidmüller’s flexible and scalable analytics solution is used to predict errors in wind power installations. This has nothing to do with “clairvoyance” or predictions from a “crystal ball”, but is based on concrete mathematical and statistical procedures that describe and analyse the behaviour of a wind turbine. The majority of wind turbines already provide sufficient data to make the installation of additional sensors unnecessary. This being the case, what does the procedure actually involve? The Weidmüller engineers begin by collecting all the available data from which the system behaviour can be learned. This data is then reduced and only the information that is actually required for gaining an understanding of the system is taken into consideration. The procedure is not just about analysing historical data, but also about making predictions. The wind turbine operator and/or producer has a key role to play in the analyses – their know-how is very important. The analysis software may well be able to predict a fault with a certain degree of probability, but to do so it always needs to have been classified beforehand. Only the user can determine whether an anomaly should actually be classified as a critical error.

The “Wind Team” specialists are familiar with the applications of their customers and are able to offer specific analytics functions for their wind power installations. The key feature of Weidmüller predictions is that they do not relate to individual components, but summarises all the available information to give a comprehensive overview of the system. Customers benefit from a consulting, engineering, software and hardware package tailored to their particular needs. The analytics software can be used on Weidmüller automation components as well as in the cloud. What the topology ultimately looks like is decided in close collaboration with the customer. Weidmüller does not aspire to provide a standard package, but always a flexible, scalable total solution.

Weidmüller BLADEcontrol® provides timely warning of damage and icing

With BLADEcontrol® Weidmüller offers an innovative system for monitoring the rotor blades of wind power installations The BLADEcontrol® sensitive sensors detect damage or icing at an early stage. This means that appropriate measures can be taken in good time, helping to prevent system downtime. In the event of serious damage, BLADEcontrol® sends a signal to the installation control unit, which stops the installation immediately and can help to prevent damage to the blades. The system consists of sensors on the rotor blades, a hub measurement unit, optional data transmission via WLAN, an evaluation and communication unit, a database server and a web-based graphical user interface. BLADEcontrol® can be used in both newly commissioned systems and existing systems. It is easy to install or retrofit.

Automation solution for small wind turbines

At the heart of every small wind turbine is its control unit. Weidmüller designs and manufactures customised boxes and control cabinets for the automation of small-scale wind power installations, such as the Top Box and Bottom Box. Customers have the reassurance of knowing that system components are manufactured in line with industrial standards. The benefits in detail:

- planning and implementation according to individual requirements

- outsourced assembly carried out by specialists

- delivery of fully tested control cabinets and boxes for immediate commissioning.

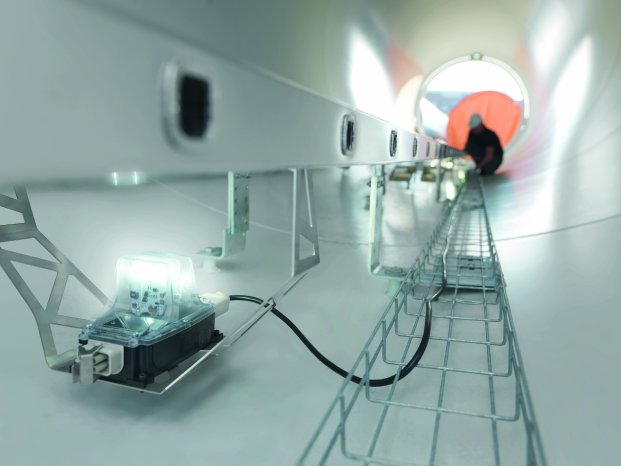

Sub-applications in wind power installations – tower ascent lighting

Weidmüller’s aim is not simply to deliver individual components but to develop solutions which simplify work processes and increase a system’s efficiency. With the “FieldPower® Wind Energy” lighting and installation system in the portfolio, that objective is fully achieved. The core element is the use of LED lights featuring very low power consumption and a long service life. Two variants have been developed for the various applications used in wind turbines: “FieldPower® MONO LED” and “FieldPower® DUO LED”. The non-directional lighting of “FieldPower® MONO LED” makes it ideal for illuminating large areas and work spaces, for example in the gondola and hub. The “FieldPower® DUO LED” has been designed for the special requirements of ascent and descent sections. Its particular design produces light in two directions and so is ideal for illuminating walkways and ladders. Together with a complete system for uninterruptible power supply, remote monitoring and a choice of outlets, it provides an optional, ready-to-fit lighting and power solution for the entire installation. The new solution is quick to install via “plug-and-play”.

Weidmüller – electrical connection, transmission and conversion of power, signals and data in the industrial environment. – Let’s connect.

Keyword: Weidmüller: solutions for wind power installations

Additional information: www.weidmueller.com