The integration in CADENAS, the cyber® simco® drive 2 (SIM2100) servo drive variant – now with optimized performance and safety features – and the cyber® distribution box underline WITTENSTEIN’s commitment to “efficiency engineering” at all levels. The aim is to excite customers and users again and again and to offer them the greatest possible, measurable benefit.

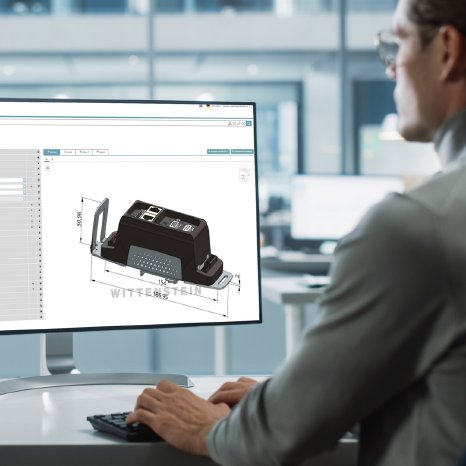

Servo solutions in CADENAS, the electronic product catalog: Faster development, faster to market

By integrating selected products from the standard portfolio into CADENAS, WITTENSTEIN provides users in the machine and plant engineering industry with comprehensive, complete, up-to-date and instantly retrievable technical product data via PARTcommunity, the globally known and established portal, as well as 3Dfindit.com, the new visual search engine. This means an enormous time saving for users of all kinds – developers, mechanical & electrical designers and project planners – because the data from the 2D and 3D CAD models, CAE models and 3D PDF data sheets is available in about 150 native and neutral CAD formats, putting an end to hours of painstaking research and time-consuming queries, requests for information or converting from generic formats. The electronic product data can be imported directly into numerous design tools without media gaps. What’s more, easy-to-understand input and output parameters simplify access to WITTENSTEIN products in CADENAS and help select relevant technical data for a specific servo solution. All of this adds up to more speed during the design process – and faster development also means faster to market.

cyber® simco® drive 2 (SIM2100): The servo drive for more performance and safety in mobile applications

The SIM2100 is WITTENSTEIN cyber motor’s new output variant in the cyber® simco® drive 2 product family. The device has IP65 protection and is designed for mobile applications in the fields of intralogistics, assembly and automation. It meets the requirements of autonomous and flexible transport systems from 500 kg to 2 tons, as reflected by its performance data – including an input voltage range from 12 to 60 VDC, continuous current of 100 A and a maximum current of 200 A. This servo drive is suitable for controlling both differential and steering units. It provides extensive safety features, for example Safe Torque Off (STO) to SIL 3 / PL e is integrated as standard. As an option, users can equip their servo drive with a safety board with enhanced safety features. Safe Brake Control (SBC) to SIL3 / PL e and Safe Position (SP) via EnDat FS to SIL3 / PL d are available in the device on request to enable safe speed, position and brake monitoring – as is a safety encoder emulation with a 1 Vpp signal up to SIL2 / PL d. No other safety-relevant components are required and wiring is greatly simplified. In practice, the cyber® simco® drive 2 also impresses with an integration-friendly design. The servo drive can be mounted in any position as well as – thanks to the IP65 protection – close to the drives, with only minimal effort necessary for wiring. All M12 industrial connectors are readily accessible on the front. The multi-Ethernet interface ensures simple and fast integration into different control worlds. An electronic identification plate and several encoder interfaces moreover allow easy integration of permanent magnet synchronous servo motors and actuators.

cyber® distribution box: Distribution module for decentralized drive axes

The new cyber® distribution box for applications with protective extra-low voltage is another addition to the cyber® simco® line toolkit. This distribution module enables low-effort, cost-efficient wiring of up to six axes in decentralized machines with a large number of distributed servo axes. More axes can be connected if necessary by adding more distribution boxes instead of drives; this cascade capability allows simple topologies to be achieved even in complex machines. The cyber® distribution box has two I/O ports for connecting an Ethernet-based fieldbus; if multiple distribution modules are cascaded, the fieldbus can be looped through via a daisy chain. Furthermore, each distribution box has six outputs for 12 to 60 VDC input voltage, which are ideal for connecting either decentralized cyber® simco® drive 2 servo drives or the servo drive system cyber® dynamic system. Owing to the IP65 protection, the distribution module integrates directly into the machine layout, saving space in the control cabinet and reducing the need for cooling. The cyber® distribution box is typically used in filling lines with servo-driven filling valves, in packaging machines with servo motors for automated format or valve adjustment, in servo-driven dosing, filling and gluing systems or in servo-electric positioners and grippers.