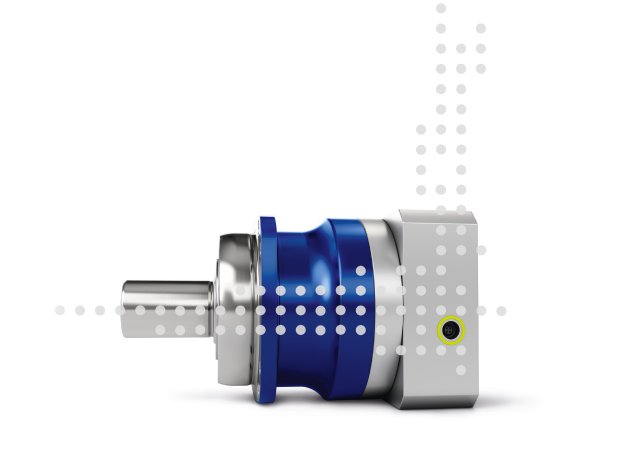

The analysis tool forms part of WITTENSTEIN alpha’s cynapse® Analyze portfolio of Smart Services and will in future be offered for all of the company’s gearboxes with cynapse® functionality – that is integrated sensors, logic and an IO-Link data interface.

Gearbox operating behavior digitally analyzed

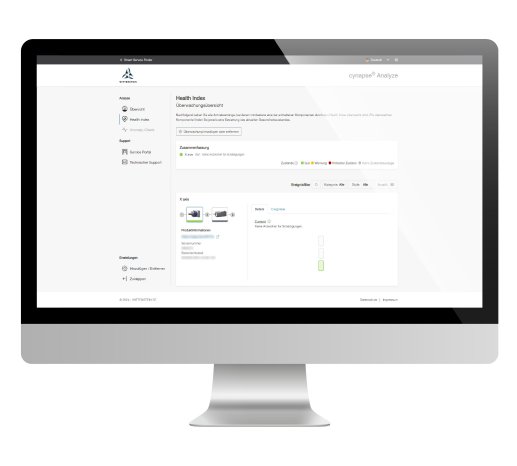

The idea behind the Health Index is to detect changes that are liable to impair proper functioning of the drive train as early as possible. The tool does this by analyzing, on the one hand, data collected by means of cynapse® and, on the other, operating data on torques and speeds. No programming effort is involved for machine manufacturers using the Health Index – not even for interpreting the data gathered. The Health Index draws for this purpose on the knowledge gained from more than 40 years of gearbox development at WITTENSTEIN alpha plus various computational models built from this expertise. Partial damage incurred by key gearbox components can now be identified more easily. The Health Index instantly visualizes all interpretable findings using a digital traffic light: green = shows no anomalies, yellow = changes identified and servicing recommended, red = risk of unplanned outages, gearbox needs replacing. Potential failure risks can be detected early in this way, maintenance assignment and services planning optimized in terms of scope and timing, spare parts or replacement gearboxes procured in good time and unscheduled machine downtime avoided. All of this promises substantial cost benefits and savings.

Who benefits from the Health Index?

The Health Index brings advantages and customer benefits not only for machine manufacturers and OEMs but also for machine operators and end users. It helps machine manufacturers and OEMs pursuing a digitalization strategy for their machinery and products to establish new, digital-based service and business models that add value to their machines and support their differentiation in the market. Manufacturers who already deploy condition monitoring systems in their digitalized machines likewise profit from using the smart analysis tool – because a smart gearbox knows its condition and reports any anomalies found.

Last but not least, the Health Index can provide pointers to how the machine is actually operated in practice; after all, drive trains are often exposed to different loads in reality than the ones they were originally designed for. The smart analysis tool can thus help to prevent consequential damage caused by excessive loading.

The Health Index is moreover of interest to operators of machines or plants with highly specific requirements. They tend to prioritize aspects such as monitoring gearboxes operating at the limits of their capacity, avoiding unplanned outages, increasing availability and safeguarding critical axes and production components. All of this adds up to a significantly lower total cost of ownership (TCO) for customers.

Smart Services: Routing, visualizing and analyzing data

WITTENSTEIN alpha’s customer-focused restructuring of its entire range of services also included the functional realignment of Smart Services in 2024. “cynapse® Connect” enables integration and routing of data. “cynapse® Monitor”, the second – and more advanced – Smart Service, offers a simple way to visualize and evaluate operating data, including setting limit values and outputting alarms if these values are exceeded. The third Smart Service – “cynapse® Analyze” – blends smart algorithms with WITTENSTEIN alpha’s core expertise in gearbox technology to create smart analysis tools like the Health Index. These “cynapse® Analyze” tools allow data from the drive train to be analyzed in real time. In other words, potential problems can be identified before they have a chance to lead to unplanned outages. This Smart Service is being continuously evolved and enhanced with new analysis tools to ensure timely access to the latest features and insights.