For many years now, WITTENSTEIN has been living and experiencing the many different aspects of security. Robustness, functional safety, freedom from defects, reliability, safe operation and - with Industry 4.0 in mind - data security are central requirements that are built into WITTENSTEIN products and solutions as features. They enable increasingly complex mechatronic motion tasks to controlled safely and reliably. This is a particular asset in markets where security, safety and reliability issues are pivotal such as medical technology, the aerospace sector, the automotive industry or energy supplies.

Aerospace: Actuators for the passenger doors of the Airbus A380

Unlike on other aircraft types the passenger doors of the Airbus A380 are opened and closed electrically. To make sure they also open reliably in an emergency, WITTENSTEIN designed the door actuators not only with the maximum possible functional safety (e.g. by integrating a redundant winding) but also with failsafe concepts embedded in the system architecture. The plane's passengers can thus be evacuated safely in precarious situations. The door actuator system is certified to the highest criticality level "A" (RTCA).

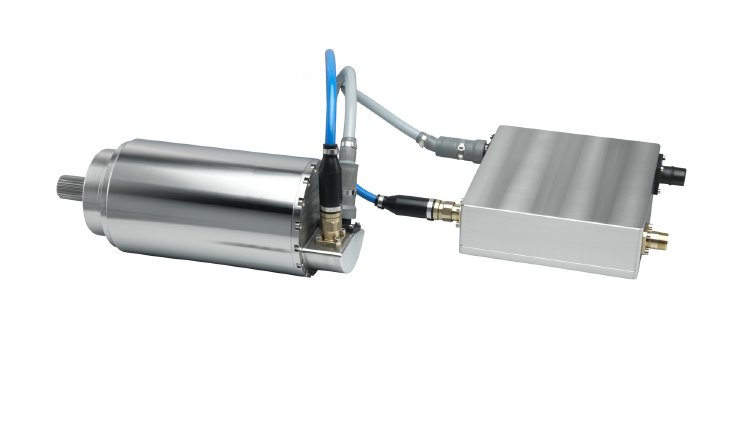

Energy supplies: Redundant AC servo actuator for use in offshore oil extraction

The explosion of the Deepwater Horizon drilling rig in the Gulf of Mexico on April 20, 2010 and the resulting oil spill, with its unprecedented ecological and economic impact, triggered an intense public debate on the degree of safety in offshore oil extraction. The WITTENSTEIN valve actuator system pumps oil through pipelines from the bottom of the sea to the surface. The frequently cited longing for safety is satisfied by the new redundant AC servo actuator system in every respect. Owing to its safety design principles, this system is certified to Safety Integration Level (SIL) 3 according to IEC EN 61508 - meeting the globally recognized safety standard for electrical, electronic and programmable electronic systems. WITTENSTEIN's AC servo actuator system makes a crucial contribution towards reducing, or even avoiding, the catastrophe risks associated with submarine oil extraction when the equipment for this purpose is used at high pressures (up to 350 bar) and great ocean depths (up to 3000 metres). Such risks are further complicated by the contact with critical media such as salt water and petroleum in an environment as inaccessible as the sea bed.

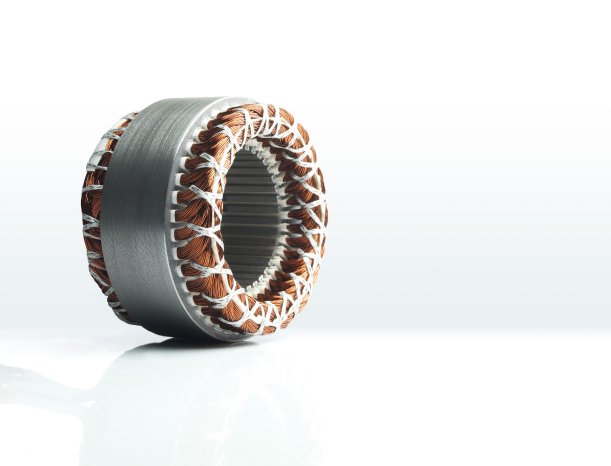

Security in many industrial environments

In addition to extreme environments like airspace or ocean floors, specialized industrial requirements also demand absolute safety. The miniaturized, highly dynamic AC servo motor made by WITTENSTEIN cyber motor is equally reliable and durable - and performs equally efficiently - at very high ambient temperatures and high pressure. In oil extraction, for example, it is used to power the drilling tools. Special materials and coatings assure the necessary temperature stability. At the same time, more efficient use is made of resources - without compromising reliability.

WITTENSTEIN alpha's stainless steel Hygienic Design gearhead was developed in response to the ever stricter hygienic requirements stipulated in the food and pharmaceutical industries. The optimized materials and special design principles effectively stop cleaning fluids or product residues from adhering to the surfaces and encouraging breeding grounds to form for bacteria. They help fight microorganisms and thus prevent contamination in foodstuffs.

Intelligent drive sensorics from WITTENSTEIN offer more resource efficiency, higher availability and hence better durability. TorqXis measures torques and lateral forces, detects critical operating states and prevents premature plant outages. Vital security, safety and reliability aspects are also incorporated into software: WITTENSTEIN's cymex® 3 facilitates efficient and functionally safe sizing and implementation of complete powertrains - and what's more, allow downsizing opportunities to be identified along with additional options for improving resource efficiency. SAFERTOS®, a safety certified real-time operating system for microcontrollers, is another example.

Security through product and process expertise is particularly important in medtech applications. FITBONE®, the intramedullary distraction nail for lengthening limbs and correcting extremities, eliminates the risk of infection inherent in external systems and paves the way for patients to be treated without pain. And how smart hardware and software can guarantee safe driving in electric cars has been convincingly demonstrated by WITTENSTEIN over the last few years with the escooter, an electric production vehicle that meets all approval conditions. Data security is a decisive factor in communication enabled electric powertrains or in connection with smart software. As a driver of innovation at the forefront of Industry 4.0, WITTENSTEIN is familiar with the many different safety and security requirements of interconnected business and value creation processes on the road to "smart factories" - and has the ability to control them safely and reliably.

The Factor S - security, safety and reliability

Regardless of how it is defined in specific situations, the Factor S - security, safety and reliability - is a key factor in the realization of efficient, controllable drive solutions for complex mechatronic challenges. The Factor S improves the productivity of machinery. It prevents contamination in foodstuffs. It saves lives. It maximizes the reliability of highly dynamic systems and facilitates oil extraction at the bottom of the sea. It optimizes pilot training. The Factor S ensures problem-free processes and guarantees undiluted driving pleasure. WITTENSTEIN is the perfect partner!