Broad portfolio

The newest WITTENSTEIN subsidiary serves our Aerospace, Industrial Systems, Special Applications and Medical Technology units with a broad portfolio of customised electronic solutions. Electronic and software components made by WITTENSTEIN electronics are already used in numerous products sold by the WITTENSTEIN Group.

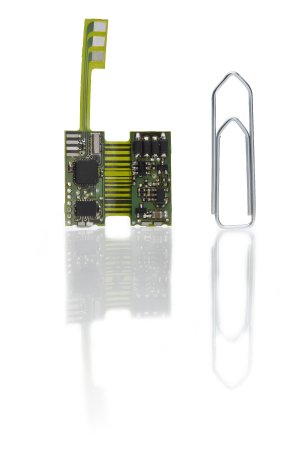

Technology implanted in the human body

A medical product manufactured by WITTENSTEIN intens provides an effective illustration. fitbone® IQ, an intramedulary nail, is implanted into the marrow cavity of a tubular bone, enabling the limb to be lengthened several inches. The miniaturised drive electronics for this innovation are condensed into just 8x20 mm². They control a motor, evaluate various sensors and transmit power and data wirelessly to the implant.

Technology drives the space conquest

A whole series of aerospace projects have been implemented in collaboration with WITTENSTEIN aerospace & simulation. All the electric drive systems in Phoenix, the EADS space transporter model, are controlled by electronic components from WITTENSTEIN. An active, flying joystick for jets and a compact, energyefficient drive unit for an aircraft cargo loading system are further successful projects in the aerospace field.

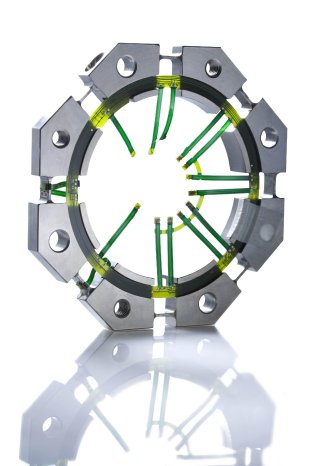

Technology – integrated and intelligent

A novel gearhead concept with integrated sensor technology for industrial applications has been developed jointly with alpha getriebebau, the biggest subsidiary in the WITTENSTEIN Group. The sensor gearhead allows process variables such as torque, force, acceleration and temperature to be measured directly. The electronics for processing the sensor data and the connection system for the sensors used were designed by WITTENSTEIN electronics.

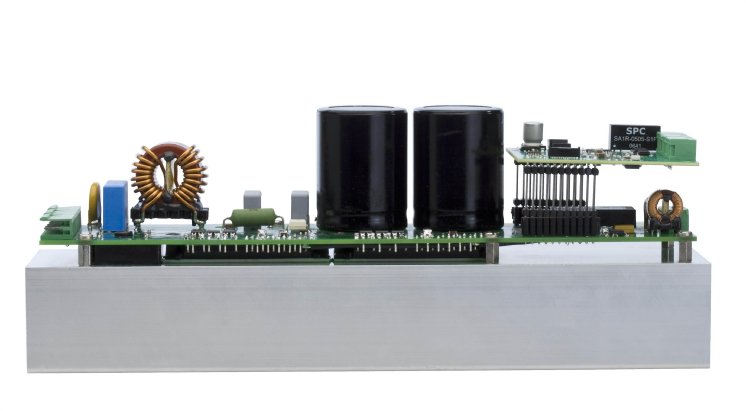

Customised solutions

One of the new Business Unit's most innovative products was developed in close cooperation with WITTENSTEIN cyber motor. This hugely successful customised solution features two highperformance servo motors operating on a compact, dualaxis controller. The motors have no feedback systems whatsoever, so that the connection technology is extremely simple. They run precisely and highly dynamically at speeds of up to 20,000 rpm. Despite their small size, they are rated for a maximum axle power of well over 1 kW in a very small space.

This technology helps meet particularly exacting requirements, for instance in special automotive applications and industrial machining processes. The fact that a feedback system is dispensed with means, amongst other things, that the motors can be used at higher ambient temperatures. Their simplified architecture reduces the customer's assembly time and enhances the reliability of the complete system. Owing to the minimal installation space, the servo motors integrate easily into any customer design. Their sensorless operation increases the availability of the drive system. Users benefit from significantly better productivity and lower costs.

WITTENSTEIN electronics GmbH extends the WITTENSTEIN Group's already impressive expertise. The company's outstanding strength lies in the customised development of electronic and software components for mechatronic solutions. The consistent implementation of a modular system facilitates a short time to market while the processoriented project processing philosophy guarantees compliance with the highest quality standards.