Special selection and sizing tools as well as comprehensive support throughout the gearhead lifecycle round off the service package for the alpha Value Line.

Completely customized: perfect gearhead solutions modularly configured

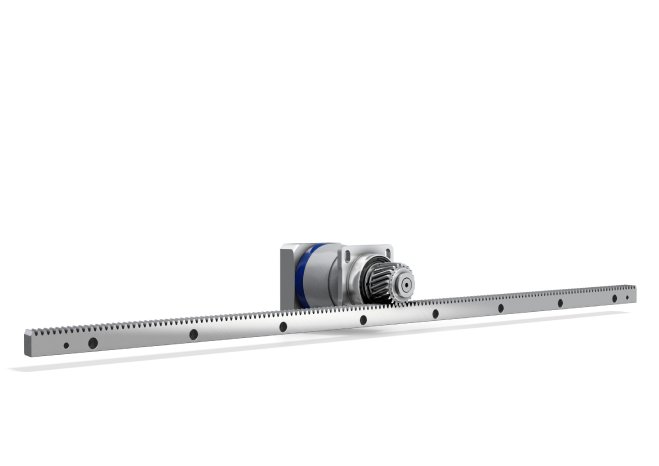

The alpha Value Line was designed to meet the diverse requirements of performance classes where technical and economic aspects have to be simultaneously optimized. Five different variants – all of them motor mounted versions – form the basis for bespoke gearhead solutions, with reduction ratios from 3 to 10 (single-stage) or 9 to 100 (two-stage) and a permissible torsional backlash of up to eight arcminutes. The output shaft can be smooth, keywayed, involute or flanged. The conditions of use, for example the presence of high axial and radial forces or continuous or cyclic operation, are a further selection and sizing criterion. Various clamping hubs and adapter plates are possible on the drive side. Pinions, metal bellows or elastomer couplings and adapter flanges mounted to the output side can also be supplied as bespoke options, depending on the model. A HIGH TORQUE version of the alpha Value Line with an output flange is offered for applications where very high torques must be transmitted. If linear motion control is required, the gearheads can be configured together with a rack as a complete linear system – the so-called alpha Value Linear System. All gearhead variants can be put together not only flexibly but also economically thanks to a special modular kit. They run very smoothly and need no maintenance at any time during their operating life – making them even more cost efficient.

Extensive possibilities and design freedom

With more than 95% efficiency at full load, the alpha Value Line impresses with extensive design freedom. In addition to a mechanical interlace which can be flexibly selected according to requirements, the gearheads allow integration in the machine in any position – vertically, horizontally or with the output facing upwards or downwards. In the system solution with a rack and pinion, the gearhead is optionally equipped with a slotted flange for quick and easy positioning of the pinion to the rack. Safe and secure mounting of the gearhead to a motor is possible in a single step, so that installation effort is reduced to a minimum.

(Not) a question of delivery time

Ordered on Monday, delivered on Friday: the fact that all gearhead components are permanently procurable and the streamlined assembly processes lie behind the rapid availability of alpha Value Line gearheads – which even stockable, prefabricated gears find hard to beat. This applies equally to large batches of up to a hundred units, where the maximum delivery time is ten working days.

Everything from one source – from sizing to after-sales services

The alpha Value Line is designed to enable very simple configuration of the gearheads using a small number of essential selection criteria. A web based Info & CAD Finder with integrated 3D files, the cymex® sizing software which generates technical assessments of complete drive trains and the professional consulting provided by WITTENSTEIN alpha throughout the design and project planning phases are other key pillars of the support strategy – and each customer's guarantee that the final gearhead solution will be optimally engineered.

Extensive support is also offered in connection with replacements: WITTENSTEIN's 24-hour hotline coordinates a range of after-sales services like pick-up and return including all shipping formalities. If necessary, new alpha Value Line replacement gearheads can be assembled and shipped by speedline® in no more than a day or two. Alternatively, with the express repair option, faulty gearheads can be expertly repaired within a maximum of five working days.

Broad array of applications for all axes

The alpha Value Line creates affordable and efficient gearhead solutions for secondary axes, linear feed motions and a wide range of mechatronic drives. Machine tools and manufacturing systems, food processing, packaging and woodworking machinery, printing and paper technology and robotics and handling solutions are just a few of the typical applications.