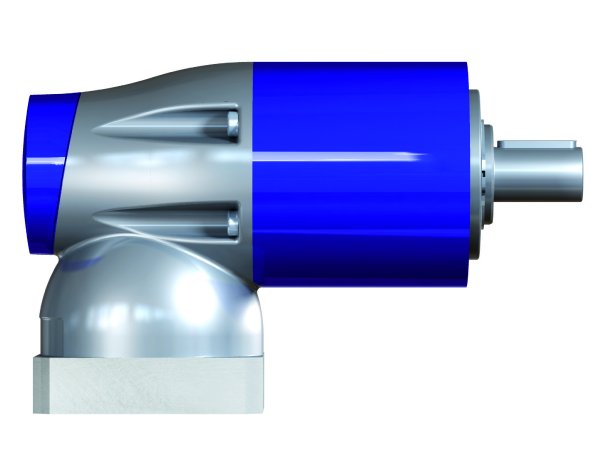

In addition to broadening alpha's already impressive product spectrum, the new right-angle gearhead marks a conscious step towards becoming a one-stop supplier of servo gearheads and mechanical drive systems. The outstanding benefits united in LPK+ are its high power density, a torsional backlash limited to 10 arcminutes, high continuous speeds that guarantee maximum productivity and rugged output bearings to prolong the service life.

Offering unbeatable value for money, this gearhead provides the perfect solution in all applications where economic efficiency is a top priority without compromising the quality standard for which alpha products are renowned. LPK+ creates unrivalled flexibility: it is suitable for any operating mode, installation position or motor type and is also included in Cymex®, alpha's unique sizing software. Designers can use this software to optimise customised applications featuring LPK+ and verify such aspects as capacity utilisation, service life and motor mounting. The new LPK+ represents an attractive alternative technology to servo worms, bevel planetary gearheads or bevel spur gearheads for servo motors.

The delivery time is normally 1-2 weeks after the start of serial production; thanks to "speedline", alpha's Europe-wide express delivery service, LPK+ can also be shipped to customers in as little as 24 or 48 hours. LPK+ can optionally be supplied with the alpha rack-and-pinion system and alpha shaft couplings. Courtesy of the universal alpha motor mounting system, the gearhead can be mounted to any servo motor in just five minutes. From positioning feed axes through motorised auxiliary axes to heavy-duty loading axes and economical rotary axes, LPK+ from the alpha stable is a versatile performer in any application that must meet exacting productivity and reliability requirements yet still remain affordable.

Technical specifications

LPK+ will initially be available in three sizes with acceleration torques up to 250 Nm. It has a torsional backlash limited to < 10 arcminutes and a peak speed of 6000 rpm. The gearhead comes with ten reduction ratios from i = 3 to i = 100 (all mathematically precise).

With its harmonious design and award-winning production processes (in the prestigious "Factory of the Year" competition, WITTENSTEIN was honoured at the end of 2006 for its "Excellent Innovation Management"), LPK+ combines a whole series of real and altogether convincing advantages that are of varying importance depending on the application. The following are no more than a small selection:

- Cartesian robots with a timing belt drive, e.g. in palletisers and loading/unloading robots: LPK+ assures high rigidity due to its planetary stage on the output side, withstands high timing belt pre-tension and - owing to its right-angle design - requires only minimal installation space. - XY axes with a rack-and-pinion drive in medium-precision flatbed machines: LPK+ unites reliable, efficient precision with a high power density, thus reducing the weight of traversing axes. Together with alpha's rack-and pinion system in the "Economy System" value class, LPK+ is available from stock.

- Positioning feed rate: LPK+ merges efficient precision with an extremely rugged design.

- High-speed axes for feeding, cutting, slotting, erecting, sealing, etc. in packaging machines: High speeds facilitated by high efficiency and the right-angle stage in an aluminium housing form the basis for high productivity. Almost zero wear and constant torsional backlash permit consistently high end product quality.