The motor select switch functions as a kind of turnout via which several motors can be selectively controlled with one single servo drive. Both the motor phases and the encoders are connected to the active motor – without compromising functionality or performance. The switching time is very short at no more than a few tenths of a second. Servo drive systems in stationary material flow systems, driverless industrial trucks with integrated load handling, packaging and bottling plants, labeling systems and machine tools – these are just some of the target applications.

Machine drives are often not all active at once

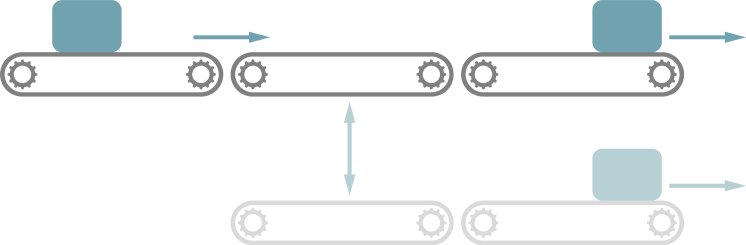

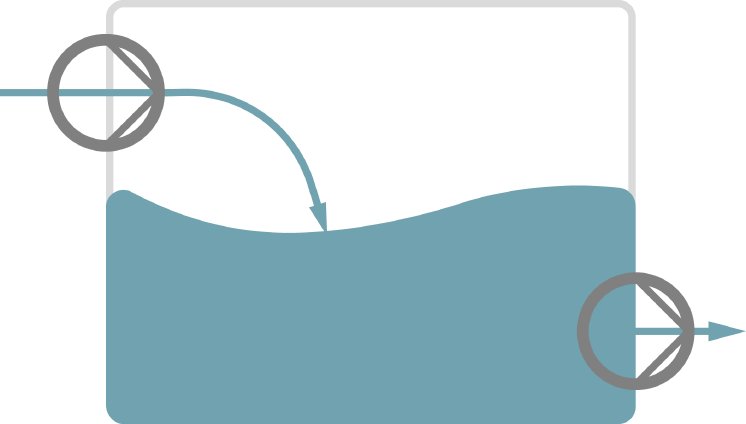

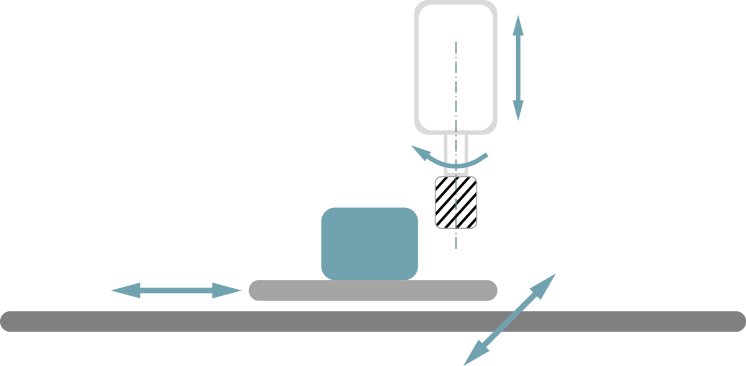

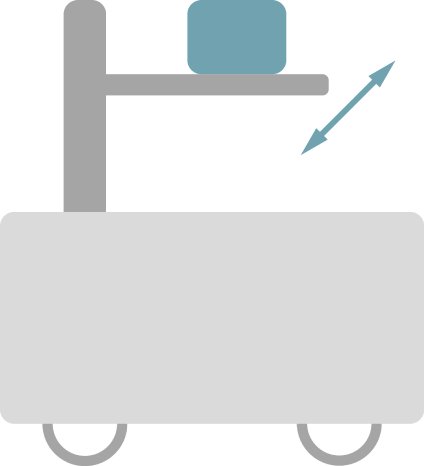

How many of a machine’s electric drives are actually in use at once? With robots or machine tools the answer is easy: usually all of them. However, there are plenty of other applications involving motion where this is not the case. Machines with an automatic format adjuster are a good example here. The machine is adjusted at the start of the batch to specific product geometries, machining depths or filling quantities. The format adjustment drives are deactivated during the production process. Their influence on the machine’s cycle time is therefore only minor and they do not have to be highly dynamic – especially as they simply take the place of actuators that have traditionally been operated manually. Material flow lines which convey workpieces or loading devices frequently consist of multiple segments and include switches as well as lifting units. By activating only the drives that are genuinely required, it is possible to manage with fewer servo drives and at the same time cut energy consumption. The situation is very similar with automatic guided vehicle (AGV) systems: during loading and unloading the wheel drives are at standstill while a feed axis transfers the load. Dosing systems and rotary tables for bottling or labeling are other potential applications. Even in machine tools, a closer look may well reveal auxiliary drives that do not all need to be controlled simultaneously, for instance the feed and spindle axes, which are idle as long as the machine’s door is being opened electrically or tools changed.

More efficiency thanks to selective drive control

The motor select switch forms part of WITTENSTEIN cyber motor’s new, modular small servo drive system and can be precisely adapted in terms of control and connectivity to any combination of a servo drive, motor and gearbox. Selective activation of four motors with one motor select switch is a typical configuration, in which the drives can be freely cascaded. The motor is selected via a digital input, which can be switched either by the servo drive itself or by a PLC. All motors not selected at a given time have no torque. Various measures, or combinations of these measures, prevent accidental torsion in the application:

- Motors with a holding brake that closes when deenergized

- Multiturn absolute encoder

- High-ratio gearbox with high backdriving torque or self-locking