Security, intelligence, resource efficiency - WITTENSTEIN traditionally integrates each of these three aspects into the development of its products and system solutions. Ever shorter market cycles, increasingly customized products and solutions and close-knit networks of services and things are associated with a growing complexity of the mechatronic drive technology. "There is a risk that systems could become uncontrollable - which WITTENSTEIN is seeking to mitigate with efficient, controllable drive technology for complex mechatronic challenges", says Professor Dieter Spath, who took over as President of WITTENSTEIN AG in October 2013.

Security - a multifunctional term

Personnel protection, the need to avoid damage to machinery and plant, optimal reliability - all of these conceptual dimensions are mirrored in the term "security". It is therefore only natural that issues such as functional reliability, freedom from defects, data security and safe operation should go hand in hand with controllability. The communication enabled mechatronic drive system specially developed for the Hanover Fair, on which a rotating 115 kg arm is conveniently braked from highly dynamic situations extremely fast and without vibration using a smartphone, will allow WITTENSTEIN to demonstrate the causal link between security and controllability.

Reliable drive technology - vital in aircraft or on the sea bed

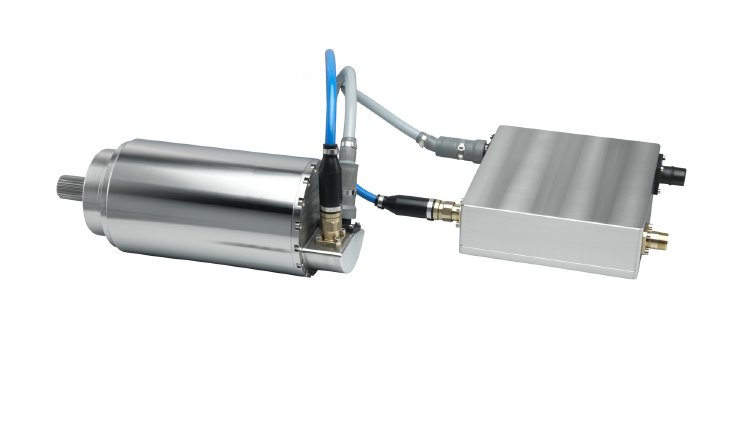

This same link is also applicable to WITTENSTEIN drive systems, such as the WITTENSTEIN cyber motor-made frameless motor in a WITTENSTEIN aerospace & simulation actuator for the doors of the Airbus A380 or the redundant AC servo actuator from WITTENSTEIN motion control that is used for oil extraction. Security through reliability helps optimize resource efficiency. Security through intelligent hardware and sensorics improves pilot training in flight simulators and eliminates problems with processes and products. "Data security is a key prerequisite in the Industry 4.0 landscape, where smart components are interconnected as a platform to create value in the future through software based services", explains Dr. Bernd Schimpf, Director Mechatronics at WITTENSTEIN AG.

Industry 4.0 as a hands-on experience

Data security is a pivotal factor in communication enabled electric powertrains or in connection with smart software. When cyber-physical production systems are realized in the framework of the future project known as Industry 4.0, it plays a crucial role alongside functional reliability. With this in mind, WITTENSTEIN will collaborate with three partners to let visitors to the Hanover Fair experience the data security aspect hands-on. Hewlett Packard will present "Virtual Fort Knox" (VFK) - a secure, federative cloud platform - together with Fraunhofer IPA. This freely accessible platform provides software based services that interact with physical products to generate additional benefits for customers and can be leveraged for new business models.

m2m-soft GmbH will show its VFK-compatible "m2m-Cockpit", a do-it-yourself software platform that makes light work of creating applications for Industry 4.0. The information received from mechatronic drives, for instance, can be entered and evaluated in a web portal very easily as a basis for value added services.

As a driver of innovation at the forefront of Industry 4.0, WITTENSTEIN is familiar with the many different safety and security requirements of interconnected business and value creation processes. The ability to control these processes safely and reliably will constitute a major milestone on the road to "smart factories". WITTENSTEIN can contribute the all-important mechatronic drive expertise and future security.

WITTENSTEIN and CyProS also in Hall 8

In addition to the main exhibition stand No. F08 in Hall 15, WITTENSTEIN will also be in attendance at the CyProS booth (Hall 8, Stand C10), which will cast a spotlight on some of the typical benefits of Industry 4.0 in real production environments.

To improve productivity and flexibility by interconnecting smart systems in the factory - in other words by fusing production and Internet technologies - is the goal of the CyProS research project, in which WITTENSTEIN has been involved as consortium leader since its launch in September 2012. In the first step, this project is concerned with building a representative range of cyber-physical modules for production and logistics systems. Next, universal procedures, tools and platforms will be made available prior to introducing cyber-physical production systems (CPPS). Finally, a technical and methodological basis will be established for utilizing CPPSs efficiently and implementing them in actual production environments like the ones WITTENSTEIN will show in the "shop window factory".