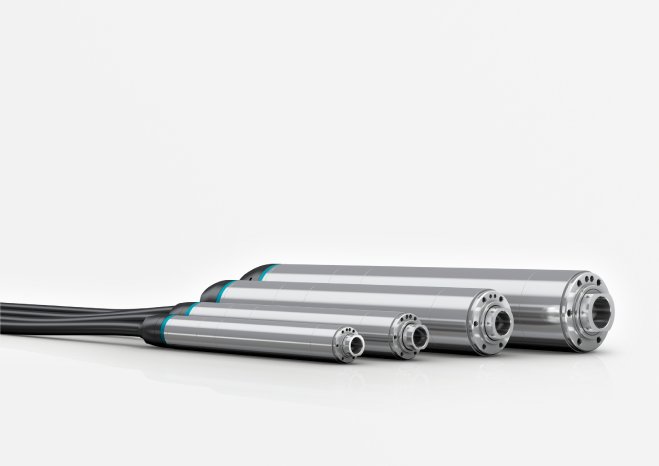

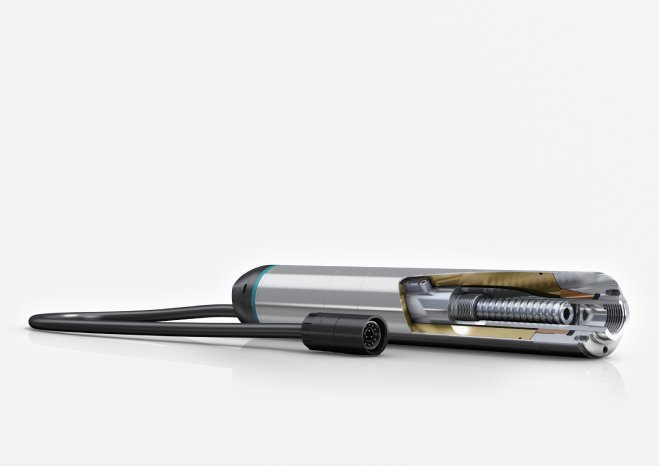

The industrial grade small servo motors can be combined with planetary gearboxes with between one and three stages for converting up to 12 Nm of torque. They also ship with several innovative features such as hybrid single-cable technology and a miniaturized, battery-free and gearless multiturn encoder. In the actuator versions with an integrated screw the servo motor, ball screw drive, linear guide and encoder system form a closed, highly integrated and ready-to-install unit. The real-time capable servo amplifiers in the cyber® simco line impress with high-resolution torque control and further improved dynamics in the current control loop. Their decentralized intelligence permits autonomous positioning regardless of the control system. At the same time, they provide a high degree of connectivity because several different fieldbus interfaces are available – CANopen, EtherCAT, PROFINET RT/IRT, EtherNet/IP or Sercos III – while the integrated safety functionality (STO) ensures the highest levels of safety to SIL3 and PL e.

Single-source small servo drive systems with no interface risks, tailored to individual requirements: more than 12,000 different motor-controller combinations can now be configured based on the modular system. A whole range of tasks can thus be handled in a future-proof way – adhering and dispensing, filling, positioning of small parts as well as positioning, joining and bending during machining operations or automated gripping – especially when maximum precision and highly flexible motions are vital.

Servo technology replaces pneumatics: Technology shift means more performance

The small servo drive toolkit from WITTENSTEIN cyber motor paves the way for solutions which, apart from maximum dynamics and precision for positioning tasks, also allow sensitively and flexibly adaptable kinematic process control – without any retooling on the machine. This represents a clear advantage compared to pneumatics based drive technology, where only limited precision and flexibility can be achieved with the pneumatic cylinders, leading to restrictions in terms of motion control. The servo technology of the cyber® dynamic and cyber® simco lines also has another benefit: complex motion profiles can be either stroke or force optimized, even in processes with short cycle times. Finally, servo scores with lower operating costs: it is far quieter, more energy efficient and more economical than pneumatic cylinders – compressed air, in particular, is expensive. What’s more, it is maintenance-free and the risk of leaks normally associated with pneumatics is eliminated along with the resulting machine downtime.

Solutions for demanding applications – sights set on new challenges

With its small servo drive toolkit, WITTENSTEIN cyber motor provides solutions for a whole series of demanding tasks such as precision dispensing of reactive resins, flexible control of robot gripping elements or highly precise motion control for the micro assembly of miniature screws. The now complete toolkit already has its sights set on new challenges in a variety of industries like packaging or industrial automation.