All three software programs, which have been extended to include the new SC+, SPC+ and TPC+ bevel gearheads and the innovative HDV+ Hygienic Design gearhead amongst others, are the perfect complement to the professional consulting expertise of WITTENSTEIN alpha's highly qualified engineers. The operator interface and navigation concept are designed to facilitate a short learning curve for novices or experts and occasional or regular users alike. Detailed, accurate product selection, sizing calculations and documentation are now a reality.

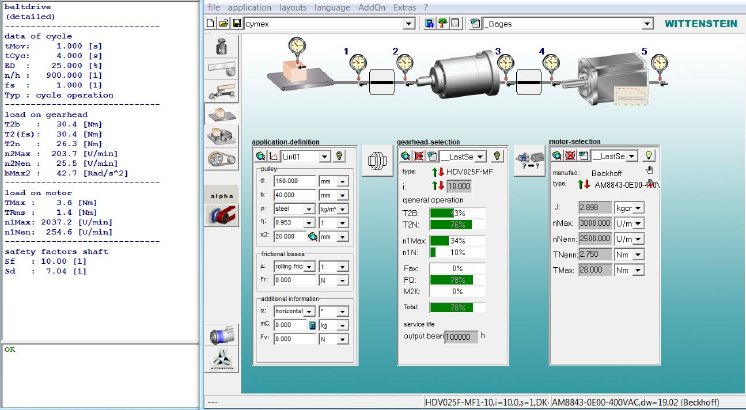

cymex®3 sizing software: quick - easy - reliable!

Application, transformation, gearhead, motor: with the newest release of cymex®3 - the proven and highly popular sizing software that sells more than 2000 licenses a year - sizing and evaluating complete powertrains is still just as quick, easy and reliable, even if very large motor and gearhead databases have to be updated. Predefined standard applications for a wide range of tasks such as belt, tape, ball screw, rotary table and rack & pinion drives simplify real-time calculations of all powertrain components. At the same time, the software is capable of abstracting all important influencing factors and customer-specific parameters, enabling optimal sizing of anything from single drive systems to complete powertrains. In addition to the product data contained in catalogues, cymex®3 also incorporates the WITTENSTEIN engineering team's longstanding experience, resulting in extended design areas - for instance for higher maximum gearhead loads or in order to identify downsizing opportunities for the drive system. Users profit from a reliable and accurate drive design in which optimal power density is a top priority. Despite cymex®3's extremely intuitive structure, interested users can also take advantage of WITTENSTEIN alpha's bespoke seminars.

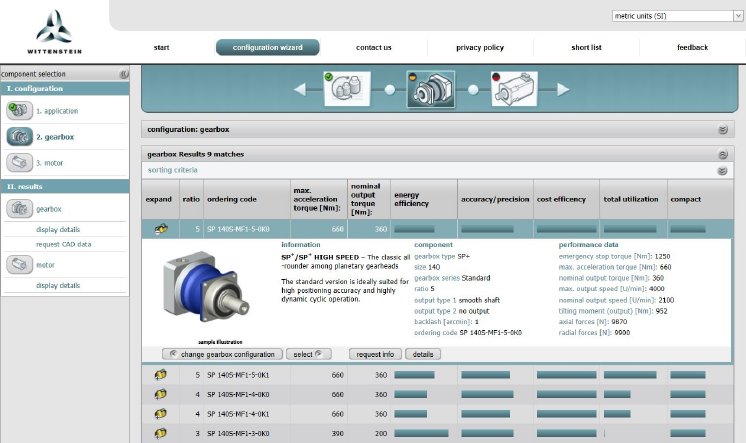

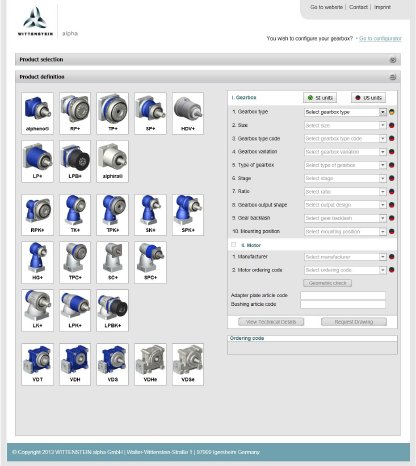

Online product configuration: multiple roads to one goal

The Online Product Configurators guide users step by step to the optimal solution, with all key parameters such as torque, speed, precision and forces entered interactively - and the option of downloading drawings or 3D models with a simple mouse click. The motor and gearhead geometries are automatically compared by the software.

Depending on the situation, each user can either specify the optimal gearhead for their particular application and then add a motor to match (Gearhead-Motor Configurator) or choose a suitable gearhead for a motor that already exists (Motor-Gearhead Configurator). The Product Configurator for rack-and-pinion systems likewise provides a fast and convenient way to configure exact fit components. All three Online Product Configurators are absolutely intuitive to use and all relevant application information is visible at a glance. The old Configurators already attracted 1500 visits a month and the new, enhanced releases have the potential for even more online clicks.

Info & CAD Finder: documentation, 3D animation and order code just a mouse click away

With its integrated motor database with more than 11,000 models, intuitive navigation and customizable 3D animations, the newest release of the Info & CAD Finder is more versatile than ever. External users, who put their trust in the predecessor version with over 2000 downloads a month, can in future reap the benefits of even easier selection when it comes to product specifications, CAD files, operating manuals and motor mounting instructions for low-backlash planetary and servo right-angle gearheads, mechanical systems, couplings and rotary servo actuators. Once the product has been selected or the solution defined, the Info & CAD Finder is an invaluable tool not only for compiling the documentation but also for creating 3D animations or generating complete order codes.

New releases of all three tools described here were made available online at www.wittenstein-alpha.de in early November 2013 - providing crucial added value for users, renewed evidence of WITTENSTEIN alpha's comprehensive consulting expertise and yet another tangible example of the company's "efficiency engineering" principle.