The exhibits inspired by real applications will underline the entire WITTENSTEIN Group’s focus on customer needs when it comes to developing, manufacturing and integrating mechatronic drive solutions. They include motors with an optimized moment of inertia in machines built by Schmale, an automatic guided vehicle from Bluebotics featuring an iTAS drive system with an integral web server, the cutaway model of an Alkitronic heavy-duty torque multiplier with integrated electronics developed by WITTENSTEIN and frameless, ready-to-install cyber kit motors in an Ehrt thread forming tool and a Velodyne laser scanner.

WITTENSTEIN will also be showing several new developments on the product side:

cyber dynamic line in a new power version

The servo motor, spindle drive, linear guide rail and encoder system as a closed, ready-to-install and ultra-compact unit – WITTENSTEIN cyber motor’s small servo motors with an integrated screw have become established in the market as drive systems for highly dynamic positioning axes. The company will take advantage of SPS IPC Drives to unveil the “short stroke dynamics” variant with a specially adapted ball screw drive for applications with short stroke movements and travel speeds of up to 900 mm/s. This latest version of the industrial-grade small servo motors, too, can be configured with a simco® drive servo controller to form a high-performance small servo axis.

simco® drive servo controller with a SERCOS interface

Connectivity means being focused on customer needs, which is why WITTENSTEIN cyber motor has now also enhanced the real-time capable servo amplifiers in the simco® drive series with a SERCOS interface – in addition to CanOpen, EtherCat, Profinet RT/IRT and EtherNet/IP. This automation bus is employed with considerable success in a variety of industries and applications – especially in complex ones with high dynamics and precision requirements. Numerous new fields of use are opened up in this way for the servo axes, comprised of small servo motors and a simco drive servo controller, where the required processing and data transmission speeds are such that Ethernet based communication in real time is a must.

Nothing but the motor: cyber® kit motors

Focus on the rotor and stator, frameless, bearingless and encoderless, open to special options – this is the concept with which cyber® kit motors create customized drive solutions for servo applications. These ready-to-install motors can be designed to meet specific requirements such as restricted installation space or very low moment of inertia. Furthermore, by varying the stator outer diameter, laminated core length and rotor variant, cyber® kit motors can be either power or torque optimized. Measuring and testing technology, electric automation, semiconductor and electronics production, assembly and manufacturing machines, robotics, handling equipment and packaging technology are only a few of the typical applications.

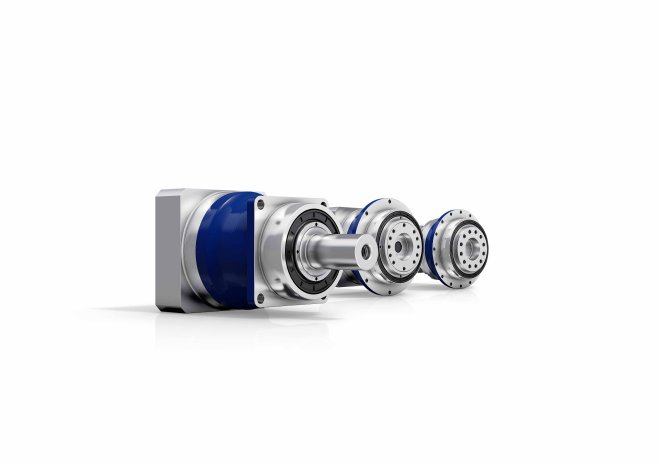

SP+ and TP+ low-backlash planetary gearheads further optimized

Higher output torques and maximum speeds with a larger range of ratios – these are the essential improvements featured in the new SP+ and TP+ low-backlash planetary gearheads from WITTENSTEIN alpha. Their increased power density enables optimal utilization of the motor’s capacity and hence even more dynamic processes. The outcome: shorter machine cycle times and higher productivity. What’s more, the expected life can now be taken into account for the first time when designing the gearheads. This customizing option helps WITTENSTEIN alpha stand out from the market standard and creates a unique selling point for the SP+ and TP+ planetary gearheads.

Advanced Linear Systems with SP+ and TP+ planetary gearheads are adequate for mid-range to high requirements. They convince with excellent value for money and can also be combined with the HIGH TORQUE and HIGH SPEED gearhead variants.

New linear systems

All linear systems with a rack and pinion have been completely re-engineered and made adaptable to each customer’s specific requirements in terms of smooth running, positioning accuracy and feed forces. Thanks to the new linear systems, WITTENSTEIN alpha now provides solutions for all axes. Preferred linear systems – available for all classes and with different output ratings – speed up the selection process and are always comprised of a gearhead, rack, pinion and lubrication system in an ideal combination. Preferred linear systems can be configured with INIRA® – the simple, fast and efficient assembly option for racks. And with cymex® 5, the sizing software, configuring the linear systems is even easier.

premo® − The actuator platform

WITTENSTEIN alpha’s premo® actuator platform unites absolute precision with perfect movement. The key aspect of this first fully scalable platform is uncompromising flexibility from the user's point of view. The result is a modular system for a very wide range of applications that is enormously versatile and can be tailored to individual performance requirements.

Invitation:

All of the above-mentioned product and system innovations will be described in detail in the WITTENSTEIN SPS IPC Drives press kit. The press kit will be handed out to you at our booth in Nuremberg.

Press representatives are cordially invited to pay a visit to the WITTENSTEIN SE stand: Hall 4, Booth 4-221.