SmartLoop is the interconnecting link between the 3D inline AOI system from Mirtec and the Y.Cheetah atline X-ray inspection system from YXLON. Abnormalities detected by the inline AOI system are analyzed in a detailed, targeted manner by the X-ray system with the help of the direct data exchange between the two inspection systems. The resulting direct feedback to production can rapidly optimize the production process and achieve distinctly increased yields in production output. SmartLoop could be experienced ‘live’ at the YXLON booth as well as at the daily special show “Solder Paste & Solder Joint Automatic Inspection Experience” from NPL & SMART Group. „This additional opportunity for ‚live‘ demonstrations of our Y.Cheetah and SmartLoop turned out to be a piece of luck, because due to the huge interest of our visitors the four systems at our booth were engaged most of the time“, Bernhard Mürkens, Vice President Electronics at YXLON, explains.

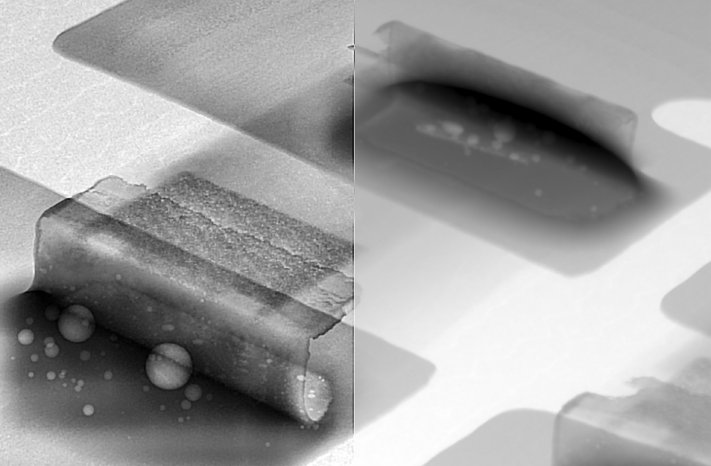

Besides the optimization of production processes by using SmartLoop, YXLON had made a point of focusing on the outstanding quality of its X-ray images. The new, advanced Real-Time HDX Imaging Engine for the graphic user interface (HDX stands for High-Definition X-Ray) allows even application users without specialized prior knowledge to generate the best image in the shortest time. Depending on the inspection item and application involved, the image is optimized for the operator in real time, the grayscale values adapt to the inspector’s viewing habits, and irregularities are detected more clearly than ever before. This means immeasurable support and invaluable time optimization for every operator in performing their inspection task.

At the YXLON Booth, visitors were able to convince themselves ‘live’ of this excellent technology. And as usual, they were eager to take advantage of the opportunity to test their own electronics parts they had brought along with them using the latest in X-ray technology.