Today’s technology is not advanced enough to operate large construction machinery by purely electric means. To meet the demands of tomorrow's construction sites, modern working machines must reduce fuel consumption and give off minimal emissions, while also remaining efficient, convenient, productive, and easy to use. ZF accepts this challenge.

More than the sum of its single parts

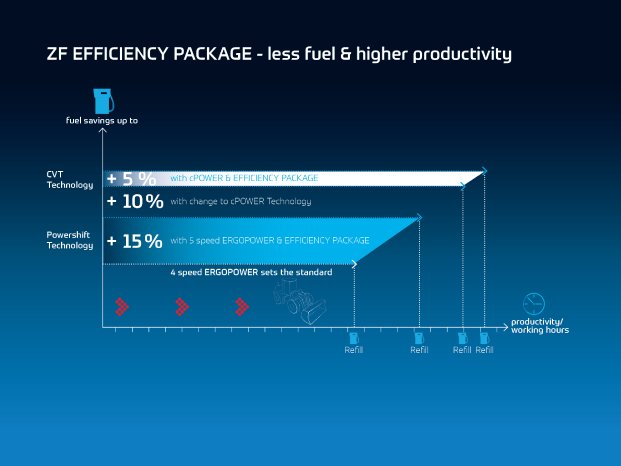

Whether its wheel loaders, dumpers, graders, forest applications or material handling - in its custom, tailor made, combi EFFICIENCY PACKAGE (fig. 2) ZF unites its expertise in transmission, axle and software development to offer more than the sum of the advantages of individual applications. System components such as ZF axles and transmissions are optimized for compatibility and enable greater efficiency and easy handling. In light of calls for sustainability, fuel savings of up to 15% are already possible with hydrodynamic technology ZF ERGOPOWER.

cPOWER CVT – a leap in technology

To meet the increasing demands for reductions in fuel consumption and higher productivity with regard to sustainability, ZF has equipped its work machinery with fully power-split CVT technology. The entire driving range, forwards and backwards, uses cPower stepless control. Regardless of driving speed, lower engine speeds provide greater efficiency and optimum comfort. The result is fuel savings of up to 25% compared to standard ERGOPOWER drives. If cPOWER is combined with the ZF EFFICIENCY PACKAGE, the fuel savings increase by a further 5%. (fig. 3)

ZF is efficiency

The newly developed EFFICIENCY PACKAGE and the cPOWER CVT technology enable ZF to tailor its solutions to customer needs and market demand. The developers have succeeded in reducing emissions and fuel consumption while increasing efficiency and productivity, without compromising on comfort. (fig. 4)