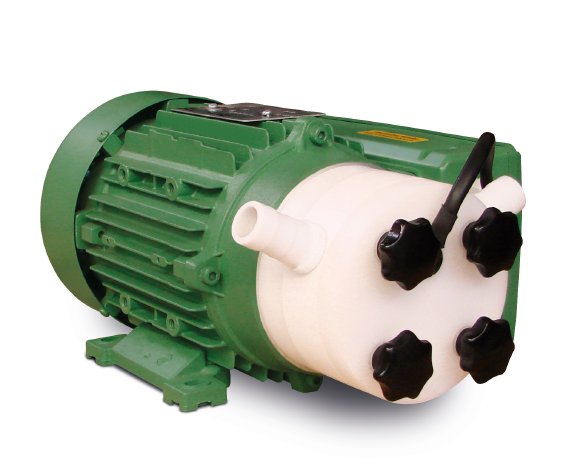

The pump is made of PTFE (TEFLON®). On account of the design the pump is dry self priming. It is not necessary to fill the pump prior to using it.

Even fluids with high viscosities or acids, solvents, bases or other process fluids can be pumped. Shaft seals made of VITON guarantee a high level of operational reliability.

This „chemical“ pump is capable of dry self priming from a depth of 3 meters, depending on the fluid the pump head is up to 50 meters. Presently the pump can be equipped with 220-400 V motors with 50 or 60 Hz, working at 1400 to 2800 rpm. Depending on the engine, the flow rate is 3 to 30 l/min. Motors are available with frequency converters also.

High grade material permit a maximum working temperature of 90 °C. Conveying fluids containing solids is possible. Depending on the model, corrosive fluids can be handled. Containers are drained down to the latest drop, practically. Transport of the media is pulsation free, another important feature for many applications.

An optional, effective dry run protection keeps the pumps from running hot in case supply of fluid is interrupted. A temperature sensor mounted to the front side of the pump stops the energy supply of the motor once a pre-adjusted temperature limit is reached.

The market introducing of the synthetic pump is scheduled for the second quarter of 2015.

See ZUWA’s synthetic pump during a visit at the ZUWA booth (booth C2, hall 9.0) at the ACHEMA 2015.