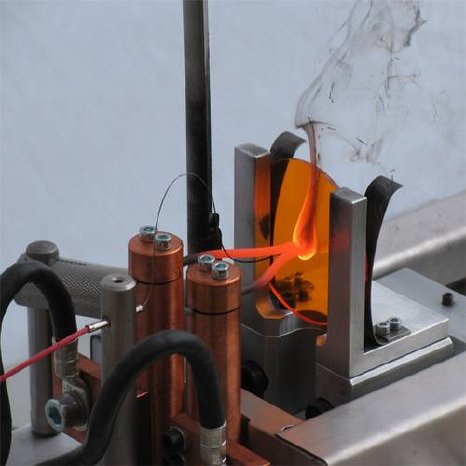

In glow-wire tests fire behavior is determined using a glowing wire pressed against a specimen. The result is then included in the properties of the plastic as a characteristic value.

EN 60695-2 contains two standardized test methods for glow-wire tests.

The glow-wire flammability index (GWFI) is a characteristic number from which is derived the extent to which a flame self-extinguishes after the source of ignition (the glow-wire) is removed after being pressed against the material. At the same time no particles which might start a fire must be given off. Example for a 2mm-thick specimen at 775° C: GWIT: 775 / 2.0.

The second test method is the glow-wire ignition temperature (GWIT), in which the ignition temperature is determined. This is the highest temperature at which the glowing wire does not cause ignition in three successive tests. Example for a 4mm-thick specimen at 850 °C: GWFI: 850 / 4.0.

Zwick's 'roboTest X' semi-automatic testing system has been developed for these two glow-wire tests on plastics and components. Plastic specimens up to 80mm diameter and from 0.4 to 4mm in thickness can be clamped in a carrier and tested using a glow-wire.

Temperature measurement is performed directly in the tip of the glow-wire via a thermoelement in compliance with the standard. Non-contact measurement using an optical temperature sensor is optionally available.

More information about glow-wire tests: http://www.zwick.de/...