LAP CAD-PRO laser projector supports intelligent positioning of equipment

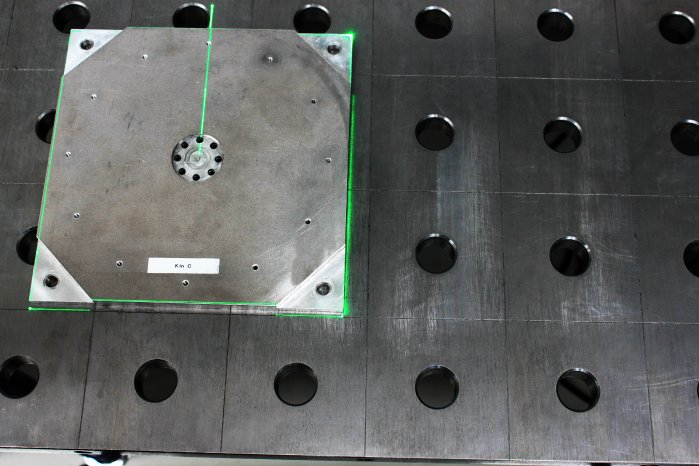

Laser-based assistance systems are an effective visual aid, specifically for small-batch productions mounted manually by a worker. In a prototypical application scenario, the CAD-PRO laser projector supports the positioning of kinematic units on the working surface. This can involve product-specific equipment or lightweight construction robots as well. The first step is the construction planning in a simulation. The kinematic units are first positioned and then checked for inadvertent collisions. In the second step, the CAD-PRO laser projector projects the position along with the orientation of the kinematic unit on the working surface. This shows the worker visually where to position the kinematic units. Once the positioning is completed, the real working scenario is measured in the third step by means of two CAD-PRO laser projectors and this is then fed into the simulation. This means that the operator needs to position the kinematic units only in a roughly correct position and the software then takes over. This saves valuable working hours.

Laser-assisted positioning of stringers on CFC shells

A second innovative application scenario is the intelligent positioning by laser projection and camera system in partially automated assembly processes. The demo unit developed by ZeMA uses lightweight construction robots to perform the plasma pretreatment and the application of adhesive to CFC shells. Stringers are incorporated for bracing the cells and are glued to the external skin. Thus far, the positioning of the stringers or clips on the shells is done by means of templates. Here, the CAD-PRO laser system from LAP comes into play: Its dimensions of 30 x 11 x 11 centimeters and weight of only approximately three kilogram make the CAD-PRO the smallest and lightest-weight laser projector on the market. Mounted above the workspace, the laser projector projects outlines and contours at an extremely high positioning accuracy of ±0.1 mm. Laser beams show the worker exactly where to position the stringers or clips to be mounted on the CFC shell.

"This is particularly convenient for small-batch products or special machine construction," explains the project head, Matthias Vette, a graduate engineer from the Zentrum für Mechatronik und Automatisierungstechnik (Center for Mechatronics and Automation Technology, ZeMA) in Saarbrücken. "The aim here is to process each piece directly and perfectly without any test runs." If everything is correct - i.e. if the adhesive seam is situated exactly according to specification - the worker issues the glue command. The robot then travels along the adhesive path.

Laser projector links man and machine

The laser system also supports the dynamic division of responsibilities of man and machine during the assembly work. "Due to its multicolor functionality, the LAP projector also serves as a link between man and machine," explains Ralf Müller-Polyzou, who is the head of Marketing and Product Management of LAP. The lines can be projected not only in classical red (diode laser with a wavelength of 635 nm), but also in green (diode laser with 520 nm) and yellow (superimposition of red and green). "This allows the responsibilities to be divided between man and machine. For example, regions with green lines can be taken on by the robot, while regions with red lines, at particularly complex sites of the component, can be taken on by the human worker." This allows optimization potentials in production to be implemented effectively by man and machine."

Laser system as the answer to the shortage of skilled workers

In the early ‘Industrie 4.0’ era, the laser-based man-robot workspace should set an example: "We aim to enable small and mid-sized companies to produce small batches economically and thus stay competitive without major expenses for programming," says ZeMA project head Vette. Because this will be a core competence in the upcoming industrial era, which large factories currently acquire through digital networking of machines and components and the increasing use of robots requiring elaborate programming. "The technology of the intuitively operated robot works pretty well already." It is aimed to support small and mid-sized companies in adapting to the demographic change and compensating for the shortage of skilled workers. "The robot can take on the simple work and allow highly qualified skilled workers to focus on the more sophisticated activities."

System can be adapted to any industrial robot

The software can basically be adapted to any industrial robot: The demonstration scenario uses the lightweight construction robot UR 10 Universal Robot, which is designed to emulate a human arm. It weighs approximately 30 kilogram, has six axes, and a working radius of 1,300 mm and is one of the first robots that can work together with humans - without any safety cage. But it is not the only one that can be used with this system. ZeMA is developing standard protocols making the software compatible with all common robot models in the market.