(Editors): Mr Keller, what kind of workpieces made from what kind of materials are typically machined on double-disc grinding machines?

Jens Keller: The most frequently machined flat workpieces include piston rings, bearing rings, pump blades and impellers, valve plates, connecting rods, clutch discs and brake discs for cars and motorbikes, even for non-motorized bicycles. Other parts include precision discs, punched, fine-blanked and sintered parts of all sorts. The parts are usually made from steel, cast iron, carbide, special alloys or ceramic. But the machines can also be used to grind magnetic materials, aluminium and special plastics.

(Editors): What makes the Nissei solution in this area different?

Jens Keller: To put it in a nutshell, the Nissei machines are extremely practical. Above all, this is because of Nissei’s vast experience in this area: the company has already sold over 700 V-5 23” models alone – both to small contract manufacturers and to large international OEMs. We have been responsible for Nissei’s sales in the USA through our branch in Detroit for a couple decades now and we have first-hand experience of customer satisfaction with these products. I think – and our customers to date will probably agree with me – that with this product, Nissei has achieved an extremely well-balanced combination of precision, user-friendliness, flexibility and cost-effectiveness. The way they come together is particularly impressive.

(Editors): Can you elaborate?

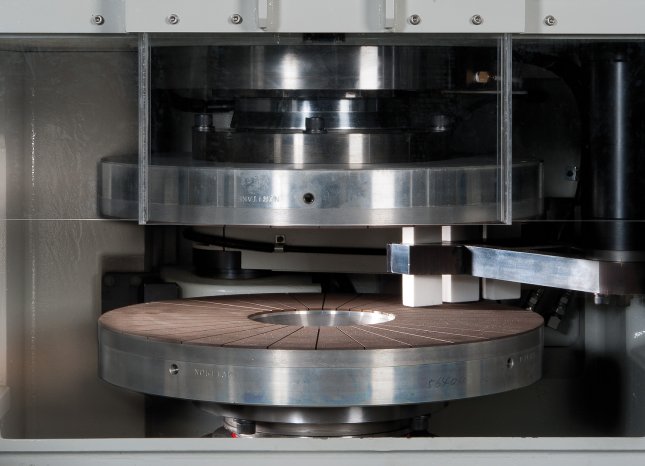

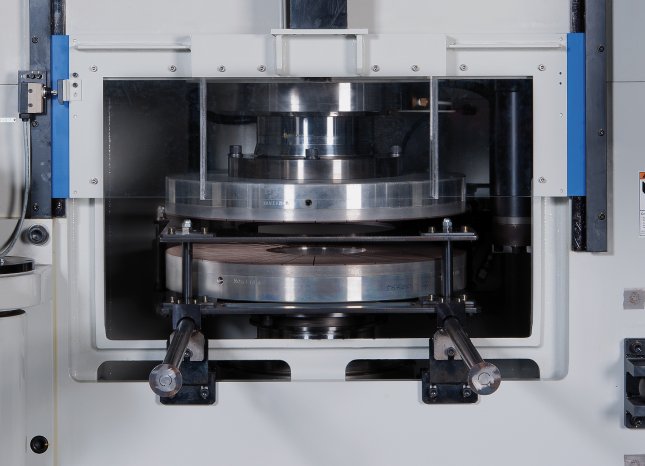

Jens Keller: The design is exemplary in terms of its purely functional, practical features. Nissei has been rigorous in dispensing with any expensive extras and frills that are superfluous to achieving the objective. The money other manufacturers invest in appearance and extras has gone here into optimising precision. The focus in the design has therefore been laid on a high degree of rigidity: closed-box frames instead of a C-frame, single-piece forged main spindles with integral GW mounting flange, clever positioning of spindle tilting mechanism, and a double-walled cast-iron frame design for temperature resistance and stability. Other precision highlights include the massive quill-slide feed system in conjunction with a worm gear, the associated patented pneumatic compensation for backlash compensation, and super-precision bearings in the ABEC-7 class. Effective standards, such as an automatic tool-wear compensation system for the lower grinding disc by means of in-process measurement, are also integrated, of course.

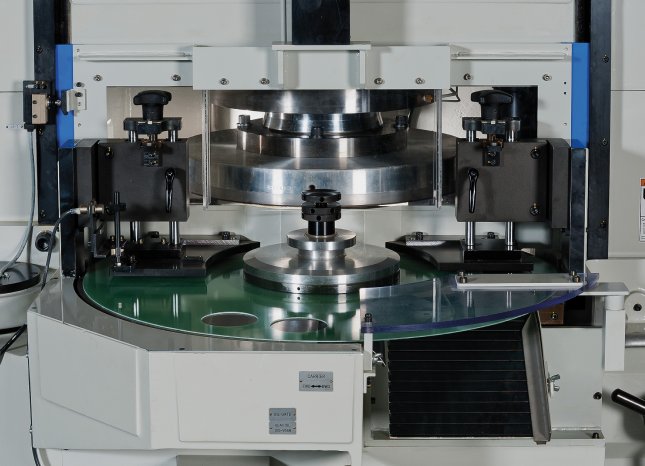

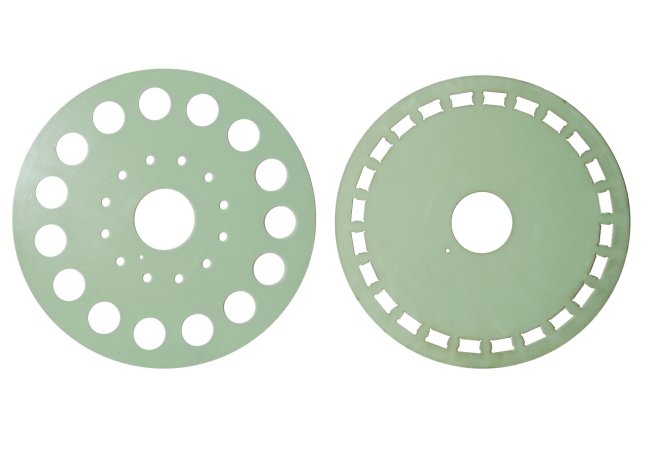

User-friendliness is another important part of the package: a swing-out housing for the rotary carrier, unique in the industry, allows the operator to change the grinding discs easily through the large front opening just a few seconds after the spindles have come to a stop. With a portable wheel-changing aid this can be done in minutes. Depending on the tolerances to be achieved, workpieces can be machined using a rotary carrier throughfeed or carrier oscillation with infeed process. For the tightest component tolerances, the workpieces can also be planetary-driven between plunge-feed grinding discs.

(Editors): To what extent is such a rigid design reflected in the workpiece quality?

Jens Keller: As you would expect, it provides great results. When machining precision steel discs with a diameter of 70 mm, for example, the machine can achieve parallelism below 3 µm and surface results of Ra < 0.5 µm with a cycle time of 0.6 seconds. In other applications, the machine achieves a stock removal of up to 0.6 mm per pass. These values not only tell us a great deal about the precision of the machine but also about its productivity. It is well known that the all-important dressing process also requires a high degree of rigidity, to create the appropriate grinding disc flatness.

(Editors): Is this reflected in the machine’s size?

Jens Keller: I would say no. Nissei has managed to compress this powerful 8 ton package into an impressively small footprint of just 2 x 2.5 m, including the control cabinet, which makes it suitable for small production areas. There are various automatic loading options for feeding and removing workpieces, ranging from part-stack magazines to robots.

(Editors): Tool options are also a part of a machine’s flexibility. What are the options here?

Jens Keller: In addition to conventional aluminium oxide or silicon carbide, the machine can be equipped with super-abrasive grinding materials made from cubic boron nitride or diamond, which, of course, require appropriate dressing technologies. Conditioning is carried out by an NC dressing unit in the machine. This is equipped with an acoustic sensor for touch detection. For super-abrasive tools, twin rotary dressing discs are also available to create the macrogeometry. Microgeometry is optimized using a second aluminium oxide sharpening arm. All set-up procedures inside the machine can also be performed through a service door on the side, and controlled from there with a simplified control panel specially set up for the purpose.

(Editors): Which workpiece sizes can be machined?

Jens Keller: The vertical double-face grinding machines are available in eight models with grinding disc sizes up to a diameter of 760 and even 915 mm. Depending on the machine model and process, workpieces have a diameter of up to 220 mm. There are methods to grind piston rings of 600 mm and more. The thinnest pieces can be just 0.8 mm thick.

(Editors): How does the cooperation between Thielenhaus and Nissei work in practice for the customer?

Jens Keller: The work is split up in a way to make the customer experience as hassle-free as possible: Nissei handles the design, assembly and running-in of the customer workpieces on the machine. All aspects of service, including dealing with enquiries, consultation, quotations and sample processing, through to commissioning, training, warranties and after-sales, are provided by the Thielenhaus teams in the U.S.A. and in Europe. As a result, customers have the advantage of a local contact that can be reached quickly throughout the project. For after-sales service, customers can, of course, use the Thielenhaus 24/7 service hotline. With this strong local support, even small and medium-sized companies can purchase and operate a machine from Japan with peace of mind, and maximize their return on investment.

Further information about double-face grinding is available from Thielenhaus Technologies GmbH, P.O. Box 20 18 55, 42218 Wuppertal / Germany, Telephone +49 202 481-360, Telefax +49 202 +49 202 450 445, or on the Internet at www.thielenhaus.com

Thielenhaus Microfinish Corporation, 42925 W. Nine Mile Road, Novi, MI 48375 / U.S.A., Telephone +1 248 349-9450, Telefax +1 248 349-9457, or online at www.thielenhaus.us