BAIER Prägetechnik, a member of the KURZ Group, develops and manufactures hot stamping machines and systems that are among the best in the world. From exterior and interior parts for vehicles, household appliances and consumer electronics to medical products and cosmetics packaging, the company's innovative developments for finishing high-quality plastic components are increasing being used for a wide range of applications in diverse branches of industry. Decisive factors include advantages such as unlimited design and personalization options, the integration of functional features and high flexibility. Compared with conventional processes such as electroplating, chrome plating and painting, the coating technology also scores when it comes to cost-effectiveness, resource efficiency and sustainability.

Effective, dry and sustainable cleaning process

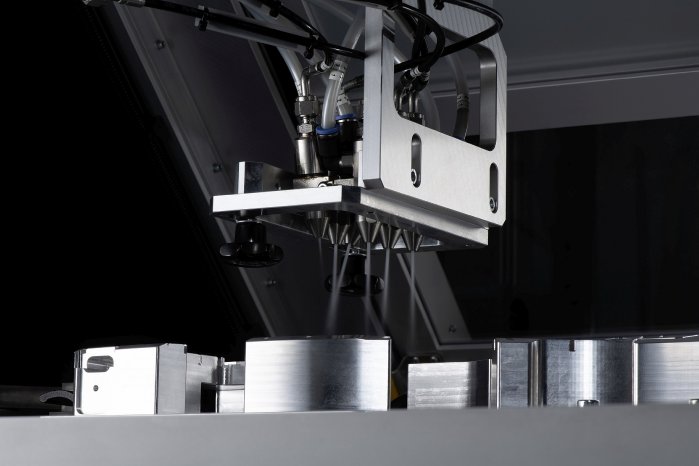

As with all coatings, clean surfaces are a prerequisite for high-quality results in hot stamping processes. Dust, particles and filmic contaminants can impair the visual appearance and adhesion of the transfer product and must therefore be reliably removed beforehand. After hot stamping, material residues may be present, especially when using metallic and transfer products with thicker coating layers and when decorating components with complex geometries. To offer customers an effective, reliable and efficient solution for these cleaning tasks, BAIER Prägetechnik cooperates with acp systems AG, the company which develops and manufactures quattroClean snow-jet cleaning systems. The quality of the company’s cleaning solution and the achievable results were decisive for the cooperation with acp.

The cleaning medium used in this dry, climate-neutral technology is liquid carbon dioxide, which is obtained as a by-product from chemical processes and from the generation of energy from biomass. Guided through a wear-free two-component ring nozzle, the carbon dioxide expands on exiting to form fine snow crystals, which are then bundled by a separate jacket jet of compressed air and accelerated to supersonic speed. The jet is easy to focus on a specific area. On impacting on the surface to be cleaned, four mechanisms (thermal, mechanical, solvent and sublimation) ensure that filmic-chemical contaminants and particles even in the sub-micron range are reliably removed. After cleaning, the surface is optimally prepared for the subsequent hot stamping process.

Residues of transfer products present after stamping are removed primarily due to the thermal effect of the quattroClean process, which causes the material to become brittle. At the same time, the force of the jet of compressed air and snow accurately shears off any material protruding from the contours. During post-cleaning, the non-abrasive snow particles and low hardness of the jet ensure that the visual appearance of the stamped on transfer product is not impaired. Cleaning is targeted, fast and meets the highest quality standards, even if it concerns decorative parts with highly complex shapes. Since the crystalline carbon dioxide sublimates completely during cleaning, the parts are dry and immediately ready for further processing.

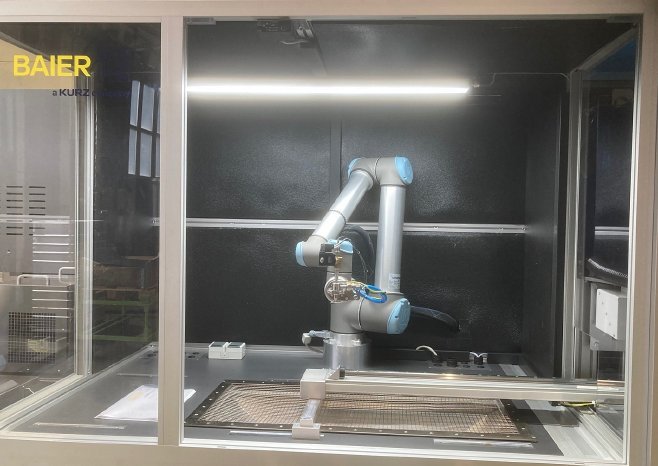

Compact, easy to adapt and digitally controllable cleaning solution

The scalable quattroClean system is easily adapted to different component geometries and can be used both for partial and full-surface cleaning. The modular design of the cleaning system means that it can be integrated into BAIER's hot stamping machines and lines or used as a stand-alone solution. To guarantee consistently good results, the consistency of the snow jet is monitored by a sensor system at each nozzle. The supply of compressed air and carbon dioxide to the nozzles, as well as the jet time, is also monitored. All process parameters measured are saved automatically and can be transmitted via standard interfaces to a superordinate system to acquire all production data. Thanks to the versatility of acp's cleaning solutions, they can be optimally adapted to the needs and wishes of customers, just like BAIER's hot stamping machines.

www.acp-systems.com, www.Baier-Praegetechnik.de