Expert Verdict

Since the end of the 70s, Alfra has been manufacturing and developing high quality tools in Hockenheim. The Standard: „Made in Germany“. „The assembly here at the site is an important reason why our customers are trusting in us“, says Product Manager Ingo Kroiss. In any case, tools for cabinet engineering have a long tradition in the company. Last year their percentage of the total turnover was more than 40 %. That’s why the specialists have every reason to be proud of their products – although a positive valuation by an expert, like the test report in the magazine “Motor&Maschine”, is highly appreciated.

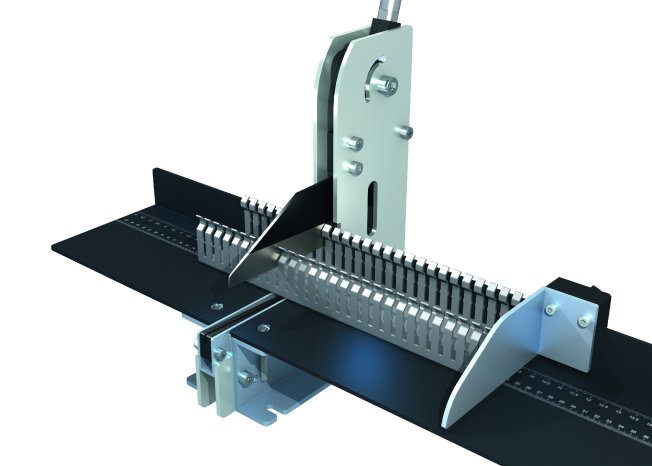

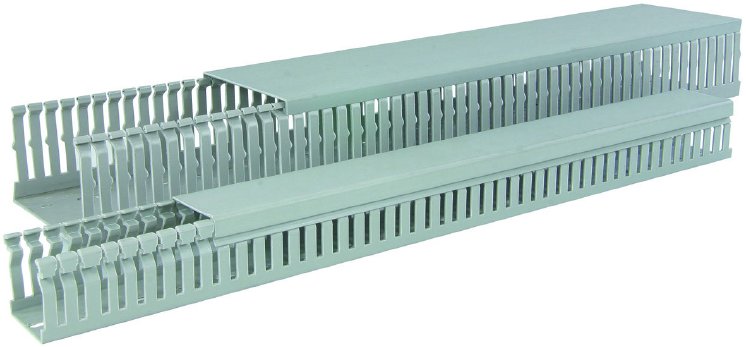

On the trial: the cable duct cutting device-VKS 125, being referred as „top class”. Included in the evaluation have been the categories “function“, „operation“ and „equipment“, whereby the user-friendliness of the cutting device had been most prominent. Ever since cable ducts have replaced fabric tape, it belongs to the daily routine of cabinet manufacturers, to cut fitting sections of the usual 2-meter-part. The option to a cutting device is a circular saw. But this would require to deburr the cut edges after sawing, because the cables in the cabinet might chafe otherwise. Burr-free cuts, without plastic splinters and annoying noise are few of the many advantages of the VKS 125. „Fundamental for the conception of our Alfra products is a close connection to our user’s workflow“, emphasizes Kroiss. „ It’s one of our most important concerns, to make our customers work routine easier“, he amends.

Proaktive thinking makes a difference

The result of this consideration is a sum of extras, improving the workflow of cutting and saving the time of cabinet manufacturers. For example the point of positioning: stabile fixing tabs, attached to the device and at the length stop, make sure that the user is able to install the VKS 125 easily on the work bench. „The full-surface supporting table prevents the deflecting of the cable duct, which ensures a precise crosscut“, Kroiss confirms. Furthermore the laser-engraved length stop with metric and inch-division is helping the craftsman to work accurately.

The heart of the unit is a sprung cutter made of hardened tool steel, cutting cable ducts and lids up to a width of 125 mm easily. With the fixed blade 90° angle-precise cutting is no problem. It’s significant that the grinding of the knife is concentrated on all available cable ducts. „This also applies for non-halogen cable ducts, which are used in places with special safety requirements, like public buildings and computer centers,” says Kroiss. The used plastics do not generate dangerous gases in the case of a fire. On the other hand, these materials are a real challenge for cutting devices because of their exceptional hardness. When the cutter is not being used, a sprung cutter protector is covering the blade to protect the user’s fingers. The enlarged opening height in the construction provides some additional scope for further applications. „That’s why the VKS 125 is suitable for ducting with special webs“, he amends.

Conclusion: Cabinet manufacturers, who have to cut cable ducts regularly, need to rely on their device. The VKS 125 is practically maintenance-free – a dependable assistant in the daily work-routine, who’s going to be indispensable in no time.