At three German locations, Alfra is producing equipment that is also showing its full potential in maritime working environments, e.g. application solutions in the field of magnetic technology. Independent of power supply, these products do not only lift reliably, but also accelerate welding processes. Alfra Rotabest metal core drilling machines with magnetic bases ensure safe drilling in any position.

Load lifting and levelling with just one magnet

When it comes to building, maintaining or repairing ships, welders and metalworkers often have to meet high standards under difficult conditions. The average time spent in a shipyard is two weeks. Time is money. For this reason, every day of it is a challenge for the craftsmen in the dock. One of the tasks: Lightning-fast welding seams, which require as little reworking as possible and withstand stringent quality tests such as ultrasound or X-ray tests.

"From this point of view, the versatility of our lifting magnets is particularly advantageous in shipbuilding," says Alfra product manager Christian Schulz. "When we think of a lifting magnet in shipyard operations, we first think of lifting flat steel, pipes or T-beams. But our permanent magnets are also excellent for use as levelling aids when welding plates and sheets," he emphasizes. These models include, for example, TML 100, TML 200, TML 250 and TML 1000. The numbers stand for the maximum load capacity in kilograms with an additional safety factor of 3:1. Thanks to the rotating load swivel, workers at the shipyard can move ship parts effortlessly and with pinpoint accuracy, for example with an overhead crane or forklift. The special plus point: if two sheets or plates of ferromagnetic metal have to be brought to the same height level and fixed before welding, the compact lightweights also do a great job. "The magnets are placed over the edges. With a single-handed operation, the craftsman activates the magnetic forces and fixes the plates at the same height in a few seconds. Conventional methods, such as a welded-on eyelet through which a wedge is driven, on the other hand, take up to 20 minutes," he notes.

Magnetic holding force from only two millimeters

Different material thicknesses are another issue in the daily operations in the dock. While four millimeter thick sheets are processed on the main deck, material thicknesses of up to 50 millimeters are not uncommon for particularly stressed structures, such as the machine foundation. This is where the patented technology of the Alfra magnets from the TML (Thin Material Lifting) series comes into play. "The magnetic field is concentrated directly on the metal, which is why there is significantly less stray loss," explains Schulz. In detailed terms this means, that depending on the model, the magnets from this line already develop considerable magnetic holding forces from a material thickness of only two millimeters.

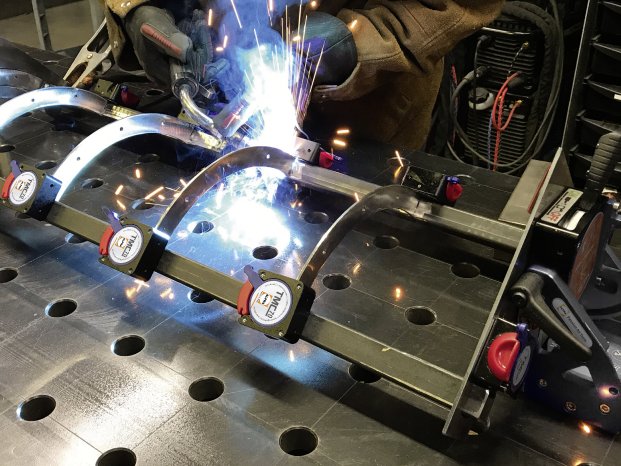

New in the product range of the tool manufacturer headquartered in Hockenheim, is the smallest magnet in the line, measuring 5x5x 2.5cm. Like all models from the product group, the TMC 70 enables welding processes very close to the magnet - because the arc that is created is only deflected when a distance of up to 15 millimeters to the tool is not reached. In addition, it is suitable for fixing guiding aids for straight welding seams on ferromagnetic materials, for example an aid for welding at an angle, or for fixing filigree metal parts that would alternatively have to be fixed with clamps.

Centered and safe at any angle

The patented technology is also a significant aspect for Alfra Rotabest magnetic core drilling machines. The permanent magnet in the base is not only ensuring smooth drilling processes due to its stable hold, but is also scoring points when it comes to "occupational safety". In shipbuilding, craftsmen often have to show their skills in working areas that are difficult to access, such as on steep metal walls or in narrow angles. With the Alfra drilling devices from the SP line, the machine adheres to the material independently of power supply. This advantage is virtually eliminating "crashes" - even when drilling "overhead". "These machines are used in demanding projects all over the world. At the moment, for example, in metal works on the Sidney Harbour Bridge," says the product manager.

A flexible partner for battery- or cable-operated drilling machines on a shipyard is the SP-V magnetic drill stand, which weighs only 6.8 kg. Its variable brackets and the Euro collar are offering a wide range of combination possibilities with different drilling machine neck diameters - for centered horizontal or vertical drilling.

Conclusion: Accelerated processes in the construction and refit of ships are gaining in importance. Well thought-out application solutions make a decisive contribution to making work in shipyards faster and safer.