EasyClean automated valves fitted to the optics ports allow the laser chamber to be sealed and the gas fill / passivation to be retained while resonator optics are removed for cleaning and maintenance.

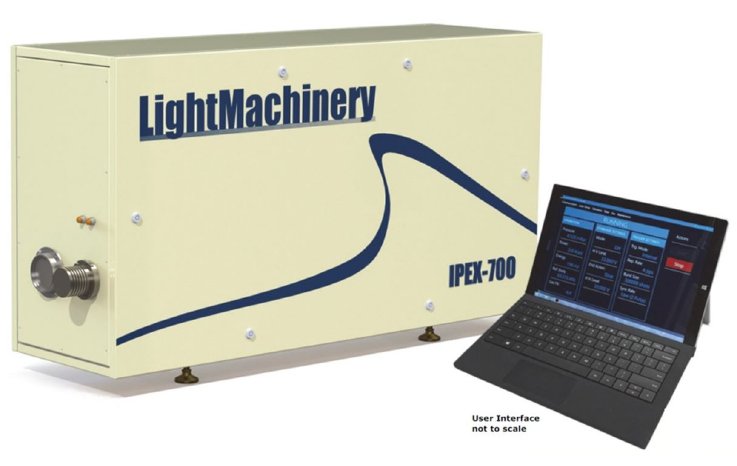

Easy to use, simple to service and economical to operate, IPEX-700 lasers combine the benefits of high precision excimer processing with the lowest total cost of ownership and highest uptime in the market today.

IPEX-700 is ideal for applications such as pulsed laser deposition (PLD). The excimer laser can be used as a means of vaporizing target material inside a vacuum chamber and depositing it on a substrate.

The process has several advantages over conventional processes including:

- a wide variety of targets can be used; metals, ceramics and oxides

- independent control on the deposition temperature and the background pressure (oxygen, helium, nitrogen...).

- the resulting thin film has the same stochiometry as the target

- novel coatings such as diamond films can be produced

- Extended gas lifetime, long replacement intervals, low operating cost

- Simplifies optical maintenance, retains gas fill and passivation

- Delivers 200 microradian pointing stability

- No realignment required after cleaning or replacing optics

- Fast, precise energy stabilization in internal, burst and external trigger modes

- Excellent energy stability, better than 1.0% (KrF).