Antonics, the DB Regio and the DB Fahrzeuginstandhaltung have built a trusting relationship over the past years.

Our first touchpoint with Colibri was in 2016, the year we won the tender of the indoor and outdoor antennas of the Colibri pilot project. “Colibri” stands for „Coach Link for Broadband Information Exchange“ and refers to a solution of modular IT-products and services for rail and road vehicles including WLAN-Services and passenger information system, vehicle diagnostics, video surveillance, automated passenger counting and a remote control function via web interface. New trains as well as existing vehicles will be equipped with Colibri technology to offer more passenger comfort and to optimize the vehicle operation and maintenance.

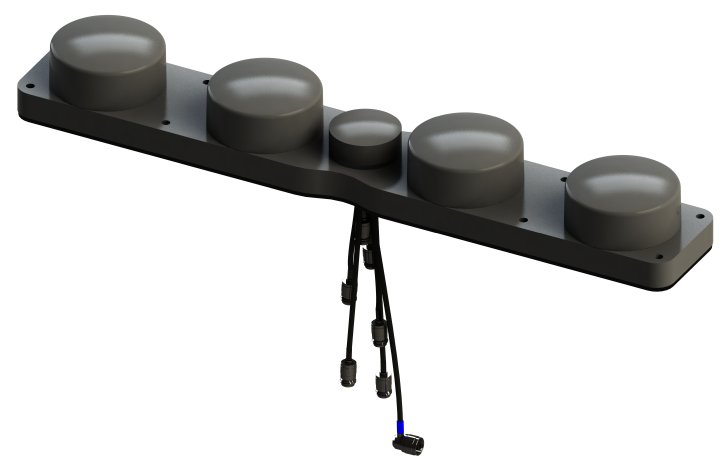

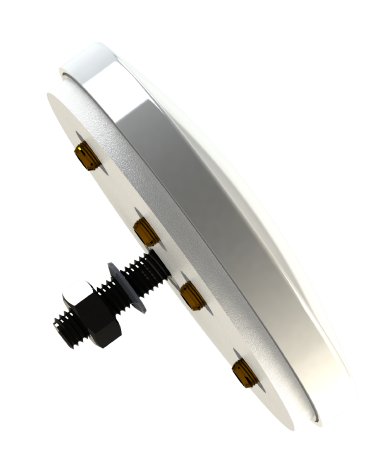

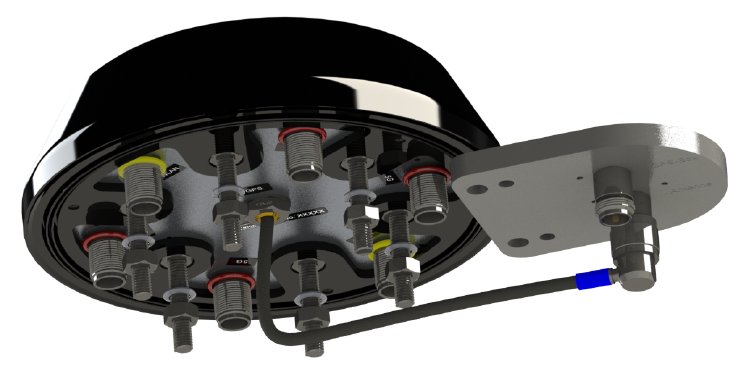

After the successful implementation of the pilot project and another European tender it’s official: As a technological leader of multiband train antenna solutions for professional radio applications Antonics will deliver for all future Colibri projects outdoor antennas (MIMO 5G, LTE, WLAN, GPS) as well as GSM-R band stop filters and indoor antennas (WiFi 6). The tender demanded explicit dual polarized roof antennas which utilize other than conventional antennas only vertical and horizontal polarized train antenna signals with different polarization to be installed in different fitting positions. This results in fewer losses due to polarization deviations between the transmitting and receiving antennas. For several years now Antonics has x-polarized train antennas in its product portfolio.

“Modern, connected rolling stock needs a stable vehicle to land connection via mobile radio – LTE and in the future 5G”, explains Thomas Derlig, team leader and market development for IT on the vehicle of the DB Fahrzeuginstandhaltung. Hence the importance of powerful antennas which can deliver reliable signals under adverse radio signaling conditions. Antonics antennas convinced in all crucial points with the requested specifications.

To complete the legalities of the Colibri project Thomas Derlig and his team from Wittenberge visited us on the 27th of January 2022 in our Velten headquarters. They used this opportunity to get an insight of our new antenna production facilities. Besides the CNC high performance milling machinery, they were impressed about the fact that we measure every single product 100% as part of quality control - to make sure that our customers do not experience any form of surprises.