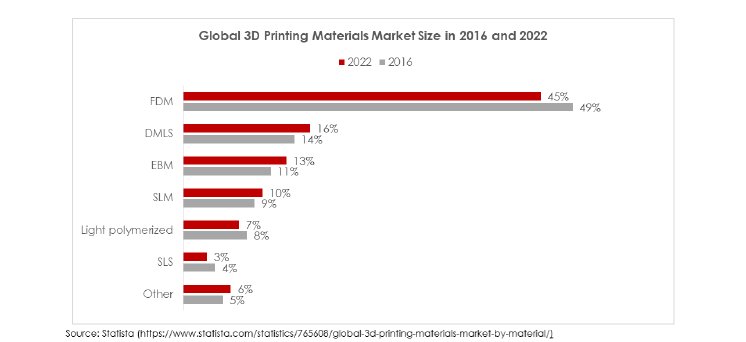

A key driver of this market size is the introduction of high performance polymers and engineered polymeric materials to the AM sector through the Material Extrusion technologies. These materials have far reaching meaning in various industries and have traditionally been processed using injection moulding or CNC milling techniques. Due to the fact that these materials are thermoplastic in nature, their properties make them difficult to process when subjected to processing methods where phase change is necessary. All 3D printing methods involve phase-change in materials. For thermoplastic materials, the processing challenge gets amplified by the fact that their microstructure can be complicated due to the formation of crystalline or amorphous domains either in exclusive terms or in co-existence. These microstructural changes can precipitate defects or poor quality 3D printed parts if uncontrolled.

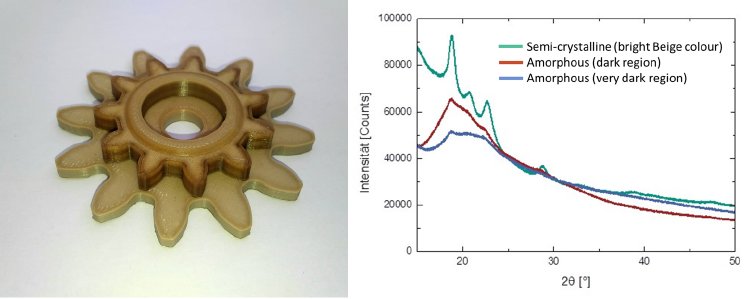

In the global AM sector Apium has historically played a pioneering role in the use of high temperature/performance polymer based materials. Its 2015 launch of the PEEK filament and HPP 3D Printer designed for this class of materials set the pace for other machine manufacturers as well as materials suppliers to make entry into this uncharted processing space. Apium has since introduced PVDF, POM-C and PEI 9085 in 2016 and in 2017 carbon fiber reinforced (CFR) PEEK. What makes Apium’s technology unique is the proprietary temperature management system. This system is specially developed for the handling of the state transformation which occurs when the solid filament material (such as PEEK) changes to the melt state then back to the solid state during the printing process. The rate at which this transformation occurs directly influences the kind of microstructure as well as the macro-physical properties of the 3D printed part.

Indeed achieving successful results with Material Extrusion (FFF) 3D printing requires good knowledge in designing for AM, the 3D printing of PEEK as well as other high performance polymers, and also a good knowledge in materials; especially how materials are created and how their properties can be engineered.

Apium`s technology has created a unique access to defining how the properties of materials like PEEK can be created from the control of the 3D printing process. PEEK parts 3D Printed using Apium’s P220 printer allow for inducing regions of different crystallinity including the literature specified crystallinity for PEEK in key applications such as medical.

The advanced technology of Apium does not only secure the crystallinity of PEEK, but also minimizes the commonly experienced 3D printing defects such as;

- Warping,

- Under-extrusion,

- Over-extrusion,

- Poor surface finish,

- Cracks,

- Poor layer adhesion,

- Gaps on outer wall.

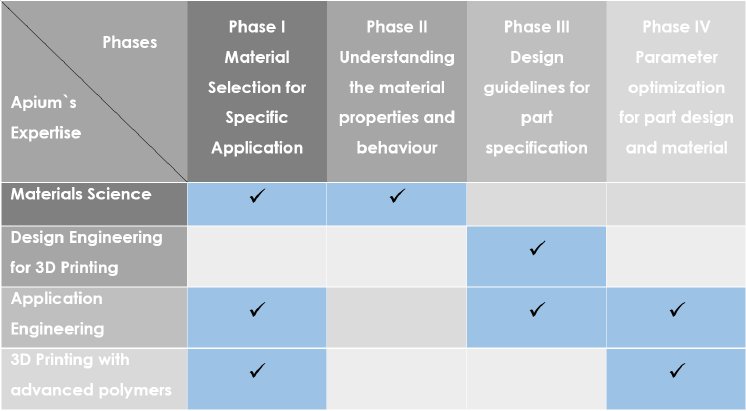

4 Phases to Successful Implementation of Industrial 3D Printing

Apium`s Applications and Services Center is dedicated to best customer experience. It consists of the best of skilled AM engineers with experience in materials science, design engineering for 3D Printing, application engineering and 3D printing of advanced polymers. The team evaluates the requirements of each end-user and establishes an advanced training program. With this advanced training program, end-users will overcome the challenges in Material Extrusion (FFF) 3D Printing of PEEK and other high performance polymers.

The Head of the A&S Center, Mr. Sasidhar Gorantla (MSc) will be at Formnext to discuss future possibilities in PEEK 3D printing and other advanced materials including metals and composites. Visit Apium at booth 3.1-C70 between 13-16.11.2018. You can set an individual appointment with Apium experts here: (the link will be added here)