Thermoplastic polymers, being the most featured kind of polymer in AM, bring along a set of properties in order to make possible their processability. These properties are typically associable to the behaviour of the polymer when exposed to temperature changes above or below its glass transition temperature (Tg). Temperature management therefore is one of the most important tasks for any 3D printer processing polymeric materials. A typical association is: the higher the value of Tg, then the greater the demand for thermal management.

Enabling Ideal Processing with High Performance Polymers

With the introduction of high performance/high melting temperature materials such as PEEK into the materials portfolio of AM, it became clear that most 3D printers are not engineered to process PEEK and its peers.

In 2015 Apium Additive Technologies GmbH build the first commercially available Material Extrusion (FFF) filament based 3D printer for processing PEEK. Apium holds a patent on its technology for high temperature polymer 3D Printing process. A unique aspect of Apium technology is the Adaptive Heating System which manages the temperature associated influences on the processed material making it possible to fabricate high quality parts.

“When materials are fed in to our 3D printers, they treat the materials just the way a professional would treat them.” Prof. Dr. Brando Okolo, CTO & Managing Director, Apium Additive Technologies GmbH

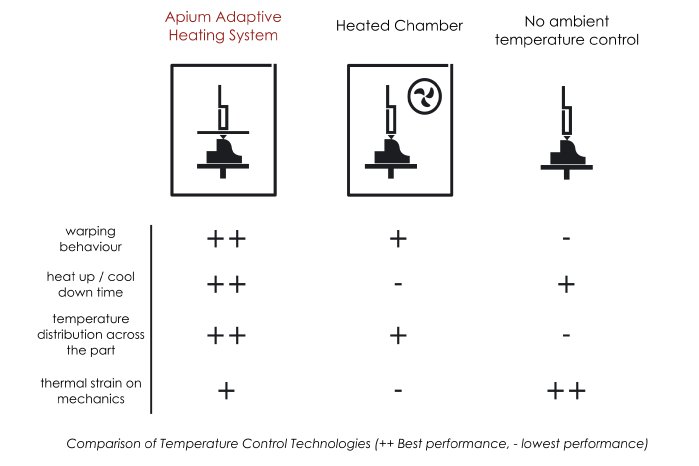

Apium Adaptive Heating System technology provides an advanced temperature control which makes possible material-specific adjustments on the printer and also aims at achieving the best temperature distribution possible in the printed part, depending on part geometry. This is a feature lacking in other commercially available Material Extrusion 3D printing technologies. The thermal management realizable from the Apium Adaptive Heating System can be used to control the degree of crystallinity in polymers which exhibit crystalline properties. This tool also improves the process quality as it provides shorter heat up and cool down times and ideally eliminates warping of printed parts.