ArcelorMittal innovations on display

Amstrong® and Amstrong® Ultra: Ultra-high-strength, high-performance steels with the largest range of dimensions and products on the market, produced up to a width of 3500 mm. They combine excellent formability with low temperature toughness. Structural steel parts become considerably lighter, thinner, higher and wider as required with Amstrong® and Amstrong® Ultra.

Relia®: Highly wear-resistant steel with minimal wear and maximum payload, which is primarily used for yellow goods. The new product line extends the life of consumables and machine components, resulting in lower maintenance costs, higher payload capacity and lower weight.

Magnelis®: A breakthrough in the field of corrosion protection. Magnelis® offers an unprecedented level of surface and cut edge protection and can be applied to a variety of steel grades. The application possibilities include: permanent coating for solar structures, optimal protection for agricultural applications or infrastructure (safety barriers, light poles), and industry applications (household appliances and electrical equipment) among others.

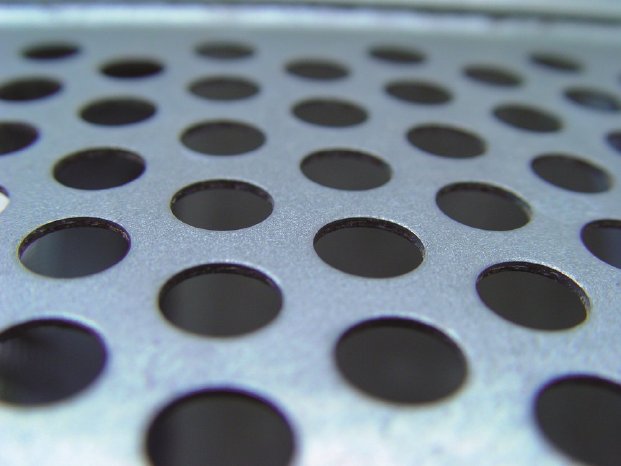

Jetskin®: Metallic coating for steel with the unique advantage of a homogeneous surface and excellent corrosion protection. Areas of application include: household appliances, electronics, computers, furniture, air conditioners. The efficiency of the new JVD process (Jet Vapor Deposition, by which the coil is coated continuously in a vacuum chamber) gives Jetskin® a low environmental footprint.

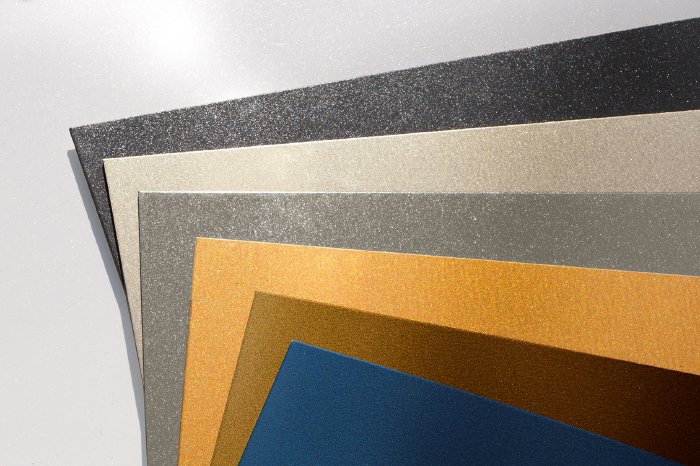

Granite® Silky Shine: Pre-painted and highly malleable steel for the construction sector; mainly used in façade systems with a high-gloss, luxurious surface (pitched roofs or architecturally designed facades). Granite® Silky Shine is tough, durable, colour-stable and offers a wide range of colours, shades and textures; with an aesthetic that is especially valued for roof and façade clothing.

ResponsibleSteel™

In addition to the product innovations ArcelorMittal will be exhibiting, Dr Alan Knight, Head of Corporate Responsibility and Sustainability at ArcelorMittal, will present the company's leading role in the ResponsibleSteel™ initiative, the steel industry's first global multi-stakeholder and certification initiative.

ArcelorMittal is a leading member of ResponsibleSteel™, reflecting its position as the world's leading steel producer. ResponsibleSteel™ was set up in 2015 as a non-profit organisation to drive a more responsible future for the steel industry. It will achieve this by building the first global multi-stakeholder certification program for the steel value chain. Certification standards will include the following areas, such as:

- Climate Change & Greenhouse Gas Emissions

- Water Responsibility & Biodiversity

- Human Rights & Labor Law

- Local Communities & Business Integrity

Explaining ArcelorMittal's commitment to ResponsibleSteel™, Alan Knight said, "responsible production techniques and high ethical and business standards are becoming increasingly important to our customers, and ultimately to their customers and consumers. We want to get to a point where steel users and purchasers have total confidence in their choices and ResponsibleSteel™ provides us with a fantastic opportunity to create the world's first certification programme for the industry and to provide these levels of confidence among customers and stakeholders alike."

ArcelorMittal will be at the Euroblech in Hall 17 Stand B 58