At the same time, the study highlights strongly the fact that if each individual item is considered in isolation, only a limited assessment can be made of the overall cost situation. For example, a 20% price reduction in the fasteners themselves would ultimately merely result in a savings potential of just a few percentage points in the overall manufacturing process.

Savings potential is available

If we think of the term ‘cost’ as being the total sum of every value brought into play in order to acquire and manufacture an economic asset, the cost of a screw fastener is made up of a total of seven factors. Depending on the amount of work involved, the development and design work will affect the budget. The same applies to the administration involved. Operating materials and tools must also be entered on the ledger of overall costs. Non-compliance control and reworking is the last of the processes in the cost chain. The fundamental cost factor continues to be the amount of time workers need to carry out manual assembly work.

Arnold’s investigation has identified major savings potential in the areas of design and development and in preparing the screw location. This integral consideration of costs, on which the Arnold investigation is based, strongly underlines the need for a vigorous partnership to exist between supplier and manufacturer. It is true to say that, even at this early stage, the decision to specify a particular fastening concept sets the course for the direction of series production costs. The potential for reducing design and development costs is achieved mainly by including a fasteners specialist into the development project team. According to the Arnold investigation, ten per cent of overall fastening costs, for example, is allocated to the design and development process, but the process will affect 70 percent of the consequential costs.

Taptite 2000 reduces costs

The investigation has identified that the area in which the maximum potential for optimisation exists is in preparing the fastener location. The choice of the fastener to be used will, ultimately, have a fundamental effect on the entire production process. In the example of using thread-forming screws that chiplessly tap into light metal, the Arnold investigation has analysed a clear time and cost savings potential. Where production processes are set up appropriately to deploy Taptite 2000 fasteners, the total investment will reduce almost as a matter of course. Since there is no need for the drilling and thread-cutting processes, there is no need for the relevant tools, such as the processing centre and washing unit required for screw locations where metric threads are used. The same applies to pumps and to the disposal systems required for the cutting emulsions, and to the measuring instruments needed to check the gauge size of metric threads. A further factor, positively expressed in the overall calculation, is the time gained in the process flow.

As a result, where thread-forming Taptite screws are integrated into a planned process, it is possible to save several hundred thousand euros even before series production begins.

Process reliability increases

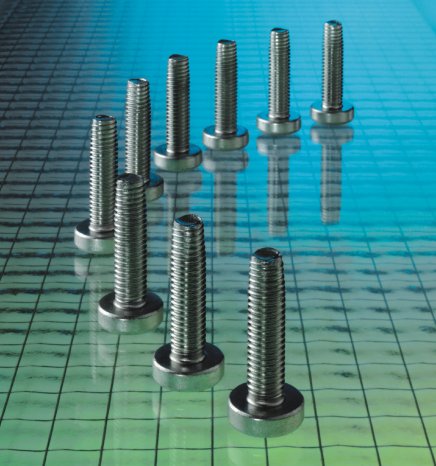

From every business point of view, compared with the traditional fastening alternatives, Taptite 2000 products are convincing - particularly for their technical quality. With their trilobular shaft Taptite 2000 screws produce low tapping torques. The radial shape of the profile means material displacement is kept low, and it cuts down on the amount of reshaping work required. Together, these two factors keep tapping torques up to 50% lower than for conventional products. That guarantees process-reliability in assembly and higher clamping power with less clamping power dispersion.

To summarise, the investigation underlines the fact that cost reductions and quality assurance in the fastening system complement each other in certain conditions. When assessing costs, it is of fundamental importance to take an overall look at the process chain and the sub-cost items involved. The decision to specify self-tapping threaded screws makes a sustained reduction in the costs involved in screw location preparation and at the same time has a positive influence on the upstream and downstream processes within the fastening system. With the design advantage of self-tapping threaded screws such as the Taptite 2000 generation, the use of fasteners of this type even opens up sustained quality advantages. However, to implement such effects, a vigorous combined partnership between manufacturer and supplier is indispensable.