Three-dimensional

The aim here was to achieve different adhesive properties on the basis of a single adhesive by varying the UV dose for cross-linking. This new technology was intended to gradually replace solvent-based adhesives.

But what exactly is UV cross-linking? In chemistry, cross-linking refers to the process by which macromolecules join together to form three-dimensional networks. This reaction alters the physical properties of the substance concerned, typically causing it to become more rigid, harder, less soluble and more thermally stable.

UV cross-linkable adhesives are adhesives that cure when they are irradiated with UV light. They consist of polyacrylates containing benzophenones which polymerize under UV light. This photochemical process sees double bonds broken down within the photoinitiator, producing radicals which immediately react with acrylate molecules. The resulting molecules have longer chains and form the three-dimensional network outlined above. This cross-linking takes place immediately after the adhesive is applied as a coating at a maximum of 140°C.

UVC

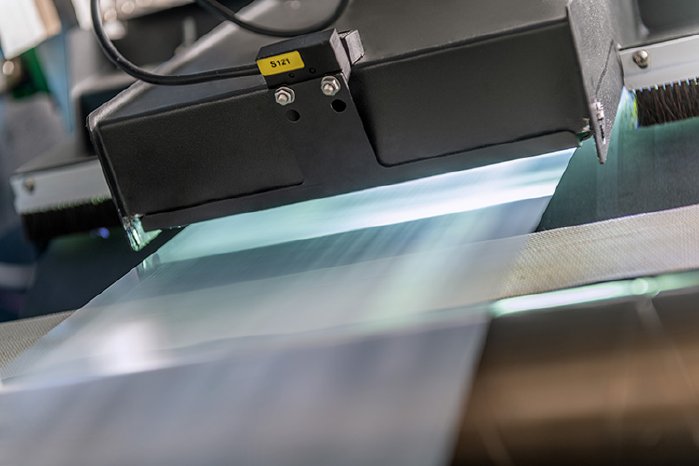

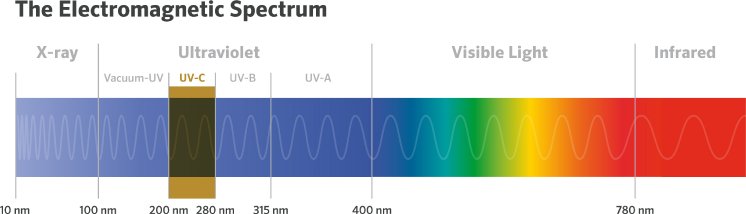

The process for artimelt products uses UVC radiation in the range of 250–260 nm. UVC radiation is distinguished from UVA and UVB waves by its shorter wavelengths and the fact that it does not occur in natural sunlight. That is why adhesives cross-linked using this type of radiation are resistant to aging and light. The UVC radiation is emitted by medium-pressure mercury lamps with a typical output power of 120–240 W/cm, the kind used in the printing ink industry. Due to the radical reaction, the cross-linking process is extremely fast. The selected cross-linking dose controls the degree of cross-linking. This in turn determines the adhesion-to-cohesion ratio and, therefore, the adhesive properties of the adhesive.

However, the short-wave UVC radiation can only penetrate an adhesive layer down to a certain depth. The deeper the penetration, the more radiation is absorbed until there is none left, and thus no more cross-linking. Consequently, the layer thickness of UV hot melts is limited.

(See graphic 1: UV - Electromagnetic Spectrum)

Constant dose

It is important that the UV dose remain constant throughout the entire coating process, which requires constant checking. If the dose decreases (e.g. because the UV lamp is old or dusty), the adhesive will exhibit a higher level of adhesion but a lower shear resistance. To keep the adhesion properties exactly the same in such cases, either the lamp output power has to be increased or the belt speed reduced. Modern all-in-one lamp systems feature measurement and control technology that measures both the UVC output and the dose, and automatically corrects itself to maintain the set value. Measuring instruments such as the UVPowerMAP, Power Puck or UVpad radiometers can be used for these checks.

Measuring the UV dose

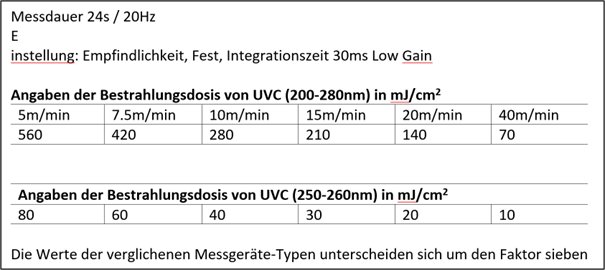

The cross-linking reaction requires UVC light in the short wavelength range of 250–260 nm. The cross-linking dose controls the adhesion-to-cohesion ratio, thereby determining the adhesive properties. The dose itself is determined by the lamp output power and the system speed.

The UV dose is measured using a UV dosimeter that is capable of detecting the UVC radiation that is crucial for cross-linking. Modern measuring instruments are able to detect UVA, UVB, UVC and UVV radiation along with the associated dose. Modern all-in-one lamp systems now feature measurement and control technology that constantly measures both the UVC output and the dose, and is able to make corrections automatically in line with the set value.

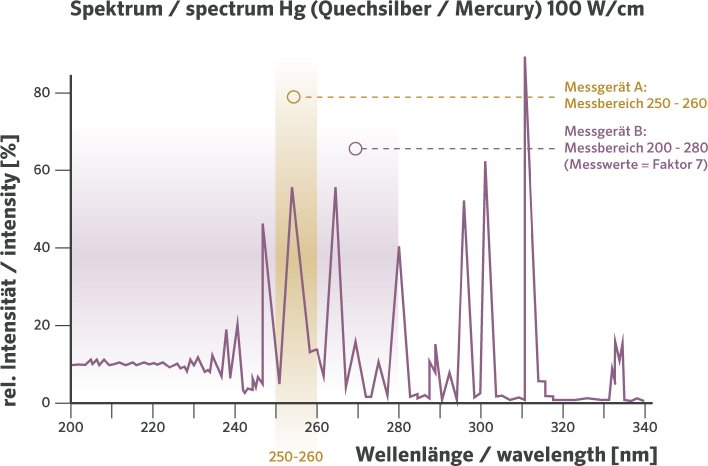

Measurements are taken in different bandwidths (spectral ranges) depending on the type of measuring instrument. The wider the bandwidth, the higher the energy absorption. There are some measuring instruments that work exclusively in the 250–260 nm range, such as the well-known Power Puck or PowerMAP radiometers. Other instruments measure the values within a bandwidth of 200–280 nm and produce measurement results that are higher by a factor of seven. Here at artimelt, we use instruments of this kind at our laboratory to confirm the values for our technical data sheets, for example.

(See graphic 2: UV - Comparison measuring ranges)

The calculation example of graphic 3 shows how the different bandwidths influence the values.

Diverse applications

The UV technology supports a wide array of applications, including adhesion levels ranging from ultra removable through to highly adhesive, which can be adjusted by varying the base polymer formulation. UV cross-linked hot-melts can also be used in damp environments. They are the preferred adhesive agent for labels at chemical companies and for resealable packaging in the case of wet wipes, which can contain alcohols, oils and emulsifiers. None of these substances is capable of interfering with the resealable properties.

Other applications include wash-off bottle labels. To recycle glass bottles, the labels must detach from the bottle without leaving residue. The label must also be easy to remove from PET bottles, before they are shredded or when they are subsequently placed in a solvent bath, for instance.

Typical adhesive tapes are not supposed to yellow and require a high degree of adhesion on various surfaces as well as high levels of shear and temperature resistance.

One special application is the highly adhesive labels containing important information – for instance in chemical plants or on car batteries. Here, the labels are exposed to high temperatures and chemical influences inside the engine compartment, including battery acid, engine oil and gasoline.

Contact with human skin and food

UV cross-linked hot-melt adhesives can be formulated so that they are approved for direct contact with the skin. They do not usually cause skin irritation. Adhesive plasters that incorporate this technology are more breathable, so they can be worn for longer than conventional products without causing the skin to wrinkle.

Radiation-cured hot-melts also meet the stringent standards for adhesives that come into direct or indirect contact with food. That is why labels printed in supermarkets are allowed to be stuck directly onto fruit and vegetables, for example. In addition, the technology also makes it possible to create resealable packaging for cookies, pasta and cheese. In particular, labels coated with artimeltfood hot-melt adhesive can be safely applied to wet or dry non-greasy foods – a property that external laboratories have confirmed through migration studies.

100% systems

Unlike dispersion and solvent-based adhesives, UV cross-linked adhesives belong to the category of hot-melt products, and are referred to as “100% systems”. This means that nothing but adhesive is applied to a carrier; in other words, there is nothing that needs to dry, evaporate or be recovered. The resulting reduction in materials and weight means significant savings on transport costs. And there is no need for dryer units or hot air (which consume energy) let alone a solvent recovery system.

Production can also be accelerated considerably, particularly in the case of heavier coating, as there is no need to wait for a drying process.

The advantages at a glance

UV cross-linkable adhesives offer several advantages over conventional adhesives that cure through exposure to heat or moisture. These include:

- UV cross-linkable adhesives cure within a few seconds, making them ideal for fast coating speeds.

- Curing under UV light ensures high strength and high adhesive force.

- There is no drying process, so the plant does not require a drying installation.

- UV cross-linked hot-melts consist of thermoplastic polymers that cure when irradiated, making them resistant to a large number of solvents and aggressive chemicals.

- They have a high level of temperature resistance: up to 200°C with short-term exposure.

- The high UV resistance also enables outdoor applications.

- They are approved for direct contact with food.

- They support applications that involve contact with human skin.

- There is no subsequent cross-linking as cross-linking only occurs in the UVC range.

It is relatively easy to switch from rubber-based hot-melts to UV cross-linked alternatives; there are just a few points to bear in mind. Anyone who processes rubber-based hot-melt adhesives will probably already have most of the equipment they need for radiation cross-linked products: a drum melter, buffer tank and applicator. In this case, the only upgrade required is UV lamps with light emissions within the UVC range. In contrast to the application head (which can be rinsed relatively easily), drum melters and hoses are extremely difficult to clean. Therefore, it is a good idea to have separate equipment for each technology; this also applies to the buffer tank.

At the detail level, the perfect UV investment ultimately depends on the breadth of the system, the speed at which it operates, the coating weight, the amount of space available for installing one or more UV lamps, and the measurement and control technology that will be used. So it certainly makes sense to seek good advice!

Note: if you are intending to use the same system for both technologies, make sure to schedule in the laborious cleaning process involved in each switch. Allowing radiation-curing hot-melt adhesives to mix with rubber-based products creates a risk of unwanted gelling, which – under certain circumstances – can lower the quality. artimelt offers cleaners for this process.

More about artimelt