In the past, fireproof solvent coatings were generally preferred. However, occupational health and safety and environmental protection on the one hand, and economic considerations on the other, called for a rethink among coating manufacturers. The development of environmentally friendly and sustainable solutions, leaving behind petrochemical products such as solvents, was and remains a key focus. The water-based technology from ASK Chemicals is a successful example of the effective transfer of expertise from solvent- to water-based technology.

Ever since its foundation, ASK Chemicals has been developing new technologies and products that benefit the foundry industry and enable the products and processes to be used in an eco-friendly manner. With SOLITEC™ DI, the company has now developed a coating technology in which the fireproof water coating used undergoes a noticeable color change as soon as it dries.

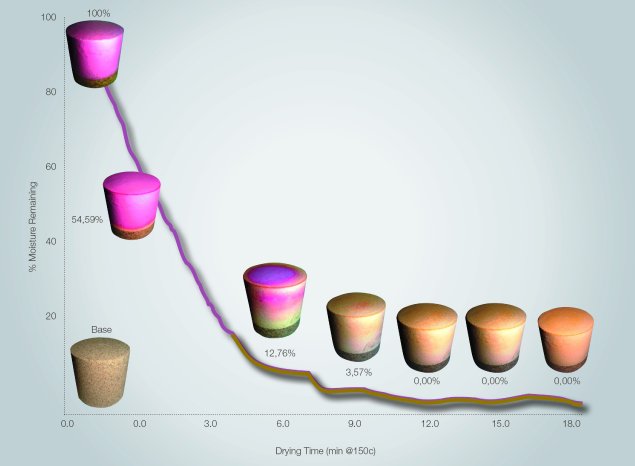

Complete drying of the coating layer is absolutely essential to avoid casting defects such as blisters, gas and slag inclusions, porosity or a rough surface finish. Although insufficient drying leads to rejection and incurs reworking costs, excessive drying is often associated with high energy costs. Both cases result in impaired productivity and reduced efficiency.

As yet, there is no simple analytical method for metal foundries to determine the coating’s degree of dryness. This gap has now been filled by SOLITEC™ DI, the water-based coating. It changes color when drying, serving as a wet/dry indicator – an unrivalled advantage for foundries. The visual confirmation of the drying state therefore makes SOLITEC™ DI an ideal quality assurance instrument for use in foundry processes.

If sand molds or cores exhibit soft areas due to inadequate compaction, i.e. loose areas with low density, these will tend to absorb more moisture from the coating than the surrounding areas, which means they take longer to dry. Here, the clearly discernible color change enables productivity as well as the core and mold quality to be optimized and monitored. Problem cores and molds are recognized easily and spoiled castings can be avoided before even greater investment outlay is incurred.

SOLITEC™ DI is already being used successfully in foundries, with the water-based coating enjoying tremendous acceptance in steel and nodular casting foundries in particular – ample evidence of the irrefutable cost benefits of solid, well controlled processes. The fireproof water coating with wet/dry color indicator is an innovative approach combining the original intended purpose, environmental considerations and a high degree of functionality in an otherwise familiar product.