Even sceptics were convinced

Jürgen Ecken, Head of Design and Documentation for RWE Power AG explained the advantages of uniformity in engineering for all of RWE's brown coal power stations. RWE's interest in introducing a sector-wide engineering solution especially motivated Ecken to speak in front of such a diverse audience.

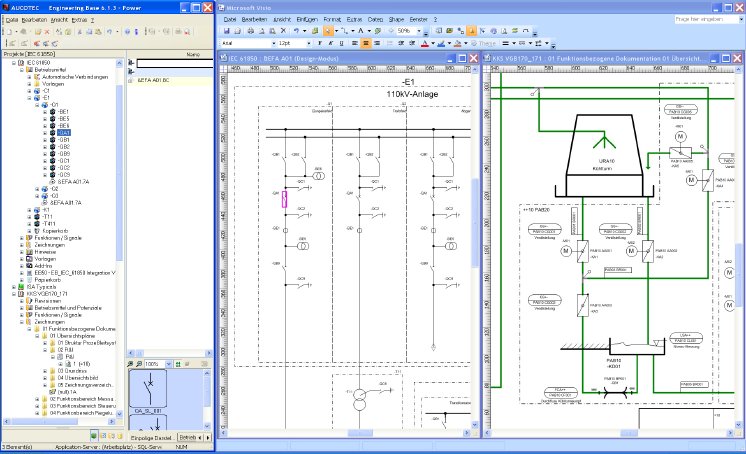

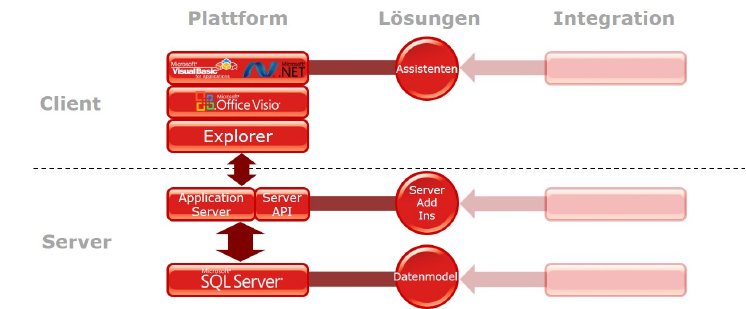

Since combining the design and documentation departments into a single centre of competence comprising 134 staff in 2000, roughly 1.2 million drawings have been digitized. In 2011, Aucotec's database-driven Engineering Base (EB) platform was introduced. The goal was to standardise the CAE software for electrical engineering and P&I (piping and instrumentation) diagrams for all of RWE's brown coal power stations. Three different tools were thus replaced immediately. Using a standard workflow with a single system at all sites, staff can be deployed more flexibly and specifications are simplified for suppliers. EB's database enables centralised master data maintenance as well as automatically updated dependent documentation, and it can be synchronised with SAP.

"During the changeover, there were certainly glitches here and there, and there are still a few things on our wish-list, but from our experience of some 3800 projects and 500 000 EB documents, I can safely state: even my sceptical colleagues would not be without the system. Despite its complexity, familiarization was very rapid and handling is now easier," explains Jürgen Ecken.

Always up to date

In the presentation given by Ernst Jäger, Emerson Process Management's Marketing Manager for Germany, the emphasis was on synchronisation of distributed control system and process automation data for efficient power station planning. Due to the widespread desire of European customers for plants from a single source, Emerson has integrated EB into its portfolio as an Ovation Documentation Builder (ODB) and linked it closely with its own Ovation automation system. This enables Emerson to have up-to-date plant documentation at any moment in time. Previously, the revision of conversion documentation up to the as-built status could take months or, in some cases, years.

Navigation to the automatically generatable documentation is carried out directly from the Ovation Operator Workstation. "Using ODB, Emerson has succeeded in closing the documentation loop," says Jäger.

"Third Generation CAE"

Kurt Oswald, Senior Key Expert from the Siemens Energy Management Division in Erlangen, gave his audience a comprehensive survey of the relevant standards and the demands and opportunities for implementation in engineering - from the first plant layouts at the planning stage through to operation and repair.

Following on from the digitized CAD drawing and the circuit diagram with derived lists, he described the EB engineering model as CAE of the third generation that has gone beyond the traditional file structure. This is an important reason for Siemens' deployment of EB as a central element of engineering in the field of energy transmission. "Today's demands on documentation cannot be fulfilled with the tool we have used hitherto, whose basic concept dates from the 1980s," explained Kurt Oswald. As an example, he cited reference designations complying with IEC 81346 and the US ANSI standard. In addition, the opportunities for process optimization in their legacy tool had been exhausted.

Time saved with the fun factor

The closing talk by Michael Wedde highlighted the network operators' view of engineering. He is head of the "Plants" department at Braunschweiger Netz GmbH, a member of the Veolia Environment Group. Starting with the first steps on a 380kV control panel pilot project for TenneT, up to today's position after several years' experience with EB's energy and utilities sector module (EVU), Wedde illustrated a variety of means by which more modern processes provide significantly greater efficiency. In the case of variant handling, the number of templates could be reduced by about two-thirds in future. Standardisation, e.g. through the use of reports, might on its own achieve a reduction in project planning time of about 20%, but according to Wedde's assessment "We are assuming that even better figures will be achieved."

He was visibly impressed by the motivational factor that the platform brought with it. "The staff really enjoy working with it," he believes. "What Aucotec have managed in recent months is massive, it really is dynamic! EB Power EVU can already be used in a range of scenarios and we can see from the breadth of today's presentations here that the system has what it takes to be the sector-wide solution for the whole energy sector. It is more than Ruplan. BS Netz GmbH is going to expand its activities increasingly in and around EB!"

All speakers concurred in their assessment of the platform's sustainability, and delegates also confirmed the desire for a sector-wide standard.

30 years' experience

Aucotec Executive Officer Uwe Vogt on Power Day: "EB embodies three decades of power experience and knowledge, gained through customer retention and covering the whole spectrum from energy generation through distribution to use, regardless of conventional or renewable sources. With EB, we want to further expand the significant market shares achieved by our "classics", Ruplan and Elcad, because the system is capable of more. With our focus on the power industry, we are a strong and reliable partner standing side by side with enterprises in this challenging and changing time. Growth of over 60% in the last five years forms a stable basis for that."