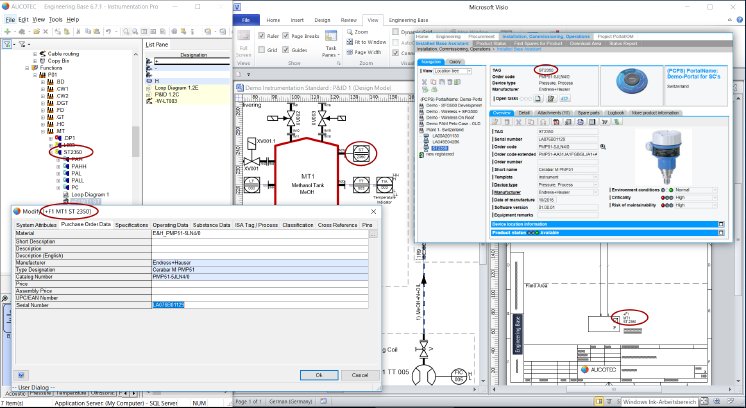

Endress + Hauser supplies this information via its W@M Life Cycle Management Portal, which houses the details of some 24 million devices. Thanks to the online portal, EB users are just a mouse-click away from quick and direct access to any specific device, whether in a list or in graphic format, and can for example compare whether the calibration of a sensor matches its originally ordered default settings, or whether there is logistical or application-related background information on the sensor in question. Users can also add information about their assets via the portal, for example entering parameter settings and transferring them to a replacement device, or quickly order a suitable replacement, among other features.

“It involves no more effort or expense than before”

Aucotec uses the portal to provide a link to EB. The three-layer architecture of this cooperative engineering platform made the link-up "as quick and simple as with any other system", in the words of Endress+Hauser’s Process Manager, Andreas Schiefelbein. “EB uses mostly ‘on-board’ resources to connect to web-based services, with no need for individual programming in .Net/VBA”, explains Norbert Ott, Product Manager at Aucotec. Users just need to ensure a corresponding match between serial number and plant-system-asset reference. “It involves no more effort or expense than before”, according to Mr Schiefelbein.

A single plant system may contain tens of thousands of measuring devices. Direct access does away with any need for duplicate data records, while making audits significantly easier to carry out, thanks to the online availability of all the certificates concerned, thereby also making bulky paper files and laborious searches a thing of the past. This shortens engineering schedules, accelerates procurement processes and increases operating times.

Networking increases productivity

An online link from the engineering department to manufacturer data is going to be up and running as early as next year at a large international plant operator from southern Germany. This involves giving each individual sensor its own “instance” and corresponding own page on the online portal, even if it shares a catalogue number with various other units. The partners involved agree that “we have managed to create a typical Industry 4.0-compatible network designed to increase productivity and reduce downtime.”