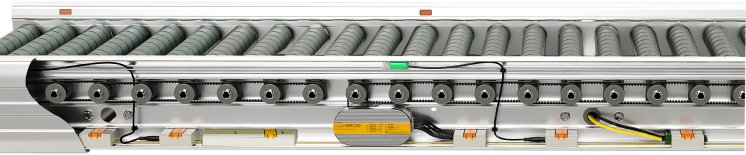

The Avancon ZPC Concept operates on zero pressure accumulation principles, offering a simple and efficient solution for controlling conveyor systems while conserving energy. All zones communicate seamlessly via decentralized control concept, allowing for easy monitoring and control from a single point of access, enhancing overall efficiency and minimizing downtime risks.

Since, our ZPC Conveyor are equipped with pre-installed controls and software for autonomous operation, it eliminates the need for additional components such as cable channels, central control cabinets, programming, and cable pulling, resulting in significant investment savings.

The Avancon ZPC Concept ensures humanconveyor interaction safety, enabling operators to work alongside the conveyor without requiring additional guarding. This validation came from the TSA, which authorized the installation of Avancon equipment at airports across North America for passenger screening purposes.

With our system, material handling integrators can optimize time and resources, enhance efficiency, and elevate safety standards, making conveyor systems more economically viable worldwide.

Material handling integrators often struggle with installation costs that spiral out of control, leading to delays, missing parts, and increased labor expenses on construction sites compared to factory settings. Avancon's ZPC Concept addresses these challenges head-on, providing a cost-effective solution that simplifies installation processes and minimizes rollout disruptions.

For more information about Avancon's ZPC Conveyor Concept and how it can revolutionize your material handling operations, please visit: https://www.avancon.com/ platform.html