Balluff sensors made of stainless steel with ECOLAB certification for example offer everything you need to make packaging processes secure, stable and hygienic. Their food grade stainless steel housing material and tested resistance to aggressive cleaning agents makes them the first choice for wet and hygienic processes in the foods industry. Various sensing principles are available for specific requirements and conditions. IP 67, IP 68 and IP 69K protection as well as temperature ratings up to 120 °C guarantee long service life and high process reliability.

Intelligent sensors for the demands of the smart factory

How modern production concepts and Industry 4.0 solutions can profit from intelligent sensors in many different ways is something Balluff will also be showing in the form of two new photoelectric sensors. These versatile units combine different measuring principles in one device and provide the switching signal via IO-Link as well as information about the sensor status and current ambient conditions. Since the sensor operating modes can also be changed on-the-fly through IO-Link, production is made flexible and adaptable to differing requirements.

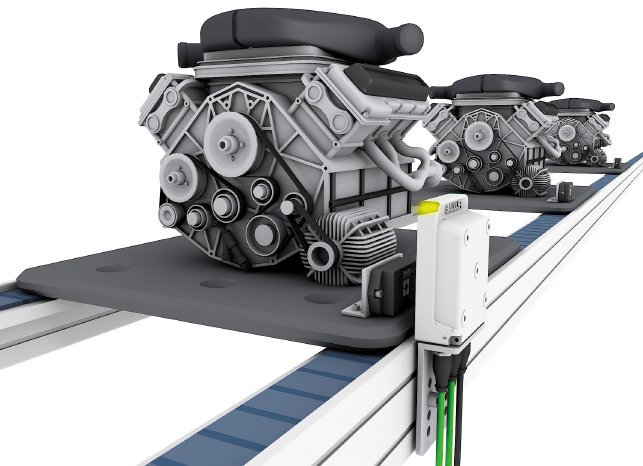

Automatic identification and tracking with RFID

Anyone interested in how format change parts can be automatically detected on a packaging machine should take a look at the RFID solutions from Balluff. These are yet another important component for implementing Industry 4.0. In addition to the proven range of rugged LF and HF systems, UHF systems (865-868 and 902-928 MHz) are available for long range requirements. These are also a proven solution for track-and-trace applications in production and logistics.

Smart vision solutions for tasks in the packaging industry

In the packaging area Balluff BVS vision solutions cover a diverse range of tasks in the fields of object detection, identification and quality assurance. The range of applications for industrial cameras, SmartCameras and vision sensors extends from comparatively easy tasks, such as reading barcodes and data matrix codes, to position-independent testing of complex characteristics as part of a 100% quality inspection in a production process.

Transmit data and power without contact

Sometimes fixed sensor and actuator cables get in the way or are subject to premature wear caused by fatigue. Here again Balluff has the right solution: Inductive coupling systems. These transmit power and IO-Link signals completely without contact over an air gap - fast and reliably. New is a solution for applications where the maximum transferable power plays a central role.

Balluff at Fachpack: Booth 4A / 4A-429