This has our ceramics:

Even in the pump industry, high-performance ceramics are becoming more and more popular.

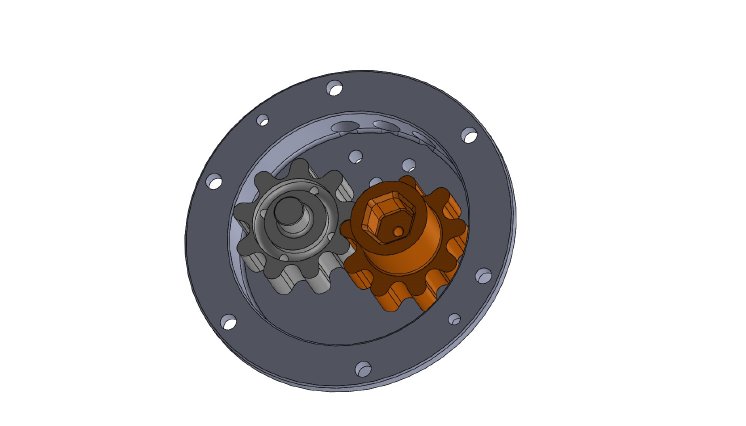

Especially with difficult-to-control media, such as liquid aluminum, the ceramic pump can exploit their advantages. The pump is completely made of ceramic and contains no foreign materials. Thus, refractory linings of any metal pipes are superfluous.

The melt-carrying parts are individually heated. Due to the special arrangement, the heating conductors have no direct contact with the hot media. The pump system can thus be tempered before immersion in the melt. Since the drive unit is completely decoupled from thermal influences by a specially developed concept, damage to the motor and the electronics is not to be expected. The pump is infinitely variable and can be operated as required within the scope of its operating range. An overload protection of the drive by means of variable torque adjustment is implemented by default. A reversal of the direction of rotation is planned, so that the system can be emptied faster and residue-free. The proportion of residual material is thus significantly reduced. Due to its outstanding material properties, the ceramic pump can be operated almost wear-free. Additional functionalities, such as a stand for storage and transport before and after pumping, can be easily adapted.

That can be our ceramic

- low tendency to adhere to NE + aluminum melts

- extreme wear, corrosion and oxidation resistance

- high strength, coupled with high fracture toughness

- very high rigidity at low density (about 40% of steel)

- extremely good thermal shock resistance

- Increasing the service life in use

- very high chemical, thermal or mechanical loads possible

- no low temperature embrittlement

- very small thermal expansion coefficient / low thermal expansion

- high fatigue strength / long-term stability