As a special feature, Baumüller offers three different options, so that manufacturers can choose the one that best meets their requirement. In the Standard Line, the pump is attached to the motor via a coupling, pump support and base flange. With its separate components, this tried and tested model offers a high degree of flexibility.

As the second build stage, the Advanced Line enables direct attachment of the pump to the motor via internal toothing in the motor shaft. Due to the omission of the pump support and coupling, installation space is saved, the installation work is reduced and the system’s robustness is improved. Moreover, the pump support is also a resonance body and its omission means that the machine’s noise emissions are reduced still further.

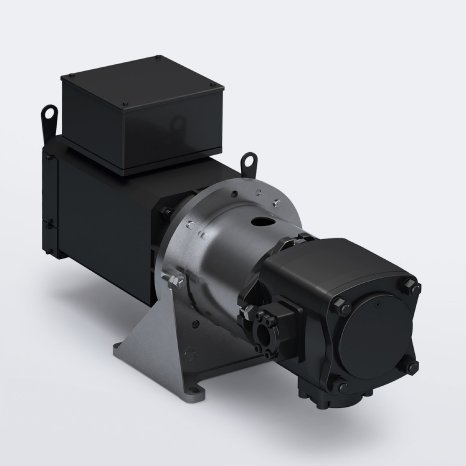

In the third stage, the Performance Line, in addition to direct attachment via the internal toothing, intelligent circulating oil lubrication is also integrated. Baumüller offers this option together with the pump supplier Bucher Hydraulics GmbH. The leakage flow of the hydraulics are routed to the internal toothing for permanent lubrication via connections on the motor and the constant pump. There is therefore no need for grease lubrication of the internal toothing, as is necessary for the Advanced Line roughly every 3000 operating hours. Baumüller is the only supplier of this patent-pending solution, which leads to significantly reduced service costs in operation. Bores in the end shield also enable the integration of leakage sensors for preventive maintenance, so that oil losses are indicated via the machine control unit. In this model an optimized shaft sealing ring with improved life also increases the system’s tool life. For improved flexibility of the motor-pump arrangement, the Performance Line build stage is also suitable for direct wall-mounting or for mounting with a separate base flange.