Other focuses at the trade fair stand include high performance drive packages, technology solutions for coordinated motion, the theme park of decentralized drive technology and new products, from the torque-optimized DSH1 servomotor series to the flexible control platform b maXX PCC-04.

Baumüller is also a partner of the first hackathon as part of SPS IPC Drives. From November 25-27, start-ups, together with specialists from the industry, will develop new technology solutions for automation.

Baumüller Life Cycle Management in Detail

The Baumüller group of companies is a full service provider and covers both the development and production of components as well as system solutions and countless service services for mechanical and plant engineering as well as for machine operators. Visitors can experience the solutions in the life cycle management live at the trade fair stand using the example of a 6-axis welding robot:

· Technology package – Automation system of the high-performance box-PC b maXX PCC-04 to the high-precision servomotor series DSH1

· Engineering – the integrated engineering Framework ProMaster for all automation tasks

· Commissioning – Virtual commissioning for quick time-to-market with the new tool ProSimulation

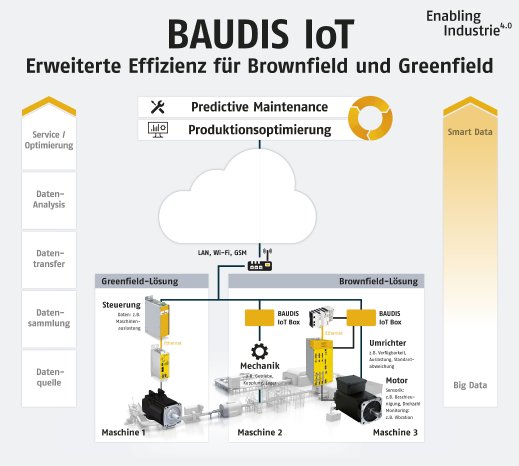

· Production – the optimization tool BAUDIS IoT for predictive maintenance and process optimization offers benefit-oriented Industry 4.0 for production

· Service – Intelligent service concepts, from machine assembly to the global spare parts concept

Decentralized Drive Technology for Industry and E-Mobility

Baumüller will be presenting decentralized drive technology for industrial and mobile applications at SPS IPC Drives 2018. Baumüller covers a power range from a few watts to 140 kW. Applications with the decentralized drive system b maXX 2500 will be shown, which are used in the textile industry as well as in the food and packaging industry, for example. The machine manufacturers benefit from significant space savings here and less wiring effort. With the powerMELA drive system, which is a joint project with Sensor-Technik Wiedemann, Baumüller offers a decentralized solution that is specifically optimized for use in mobile commercial vehicles and work machines.

Modular Technology Solutions for Coordinated Motion

Time-to-market is becoming increasingly important in mechanical engineering. Manufacturers who would like to develop multi-axis machines with basic functions, such as milling or cutting or even individual motion sequences, with little effort receive a modular automation solution with the technology package from Baumüller for coordinated motion. This is available as a basic package for linear, machine-independent motion guidance as well as a complete solution for applications with several axes responsible for the movement guidance and additional auxiliary axes.

The kit consists of the necessary automation and drive components, including software solutions for the development of any motor-driven motion sequences in production and automation technology. The main advantages of using Baumüller's technology solutions for multi-axis applications are the reduced costs, the simple handling during the project planning and commissioning and therefore the shorter time-to-market.

Industry 4.0: Predictive Maintenance

Industry 4.0 opens up many new opportunities: customized products, optimized production processes and predictive maintenance. The prerequisite for this is the acquisition, communication, algorithmic linking and intelligent evaluation of data. Baumüller offers numerous products and solutions for Industry 4.0, including BAUDIS IoT, a system for the process optimization and predictive maintenance of existing and new machines. It is an IoT-capable system that allows for a simple networking of machines and systems via the Internet and the intelligent analysis of data. BAUDIS IoT can be used independently of the manufacturer of the automation components and the sensors and therefore can easily be retrofitted and upgraded. It is therefore equally suitable for greenfield and brownfield plants, i.e. for the digitization of new and existing production plants.

Digital Twin for Shorter Time-to-Market

Making machines and systems future-proof and tailor-made for applications requires time and experience in engineering. In order to shorten the development time and bring the machine to market as quickly as possible, Baumüller offers software models for the simulation of its drive components and makes them available to the machine manufacturer in the project planning phase for the new machine. The models support open standards and can be used with all common simulation tools.

Alternatively, Baumüller provides engineering support and takes care of the entire machine design. A major advantage of simulations is the faster time-to-market, since the software can be tested virtually during the development phase of a machine. This allows the interaction of the individual components to be evaluated and optimized in advance.

Product Highlights

The Biggest High-Torque Motor: Previously the largest produced motor of the high-torque series DST2 will be an eye-catcher at the trade fair stand, which is expanding the portfolio with respect to performance and speed. Six sizes are now available with the new 560 size. The DST2-560 meets the highest requirements in direct drive technology with a rated torque of up to 38,000 Nm and a maximum torque of up to 80,000 Nm. DST2 high-torque motors are now an optimal solution for numerous types of machines, from press to tool and plastics machines to ships. With an optimally segmented offer of motors on the market, in addition to different high-torque motors Baumüller also offers efficient and scalable servomotors as well as main drives in numerous versions and sizes.

Compact Water-Cooled Servomotors: Baumüller is expanding its portfolio of servomotors to include the water-cooled model sizes 45 and 56. The efficient water cooling allows for a very high rated power density. This therefore covers applications that have high requirements with respect to dynamics and that at the same time have a high effective torque. The immediate surroundings experience minimum stress from motor heat with the heat dissipation through the water cooling medium. Application areas include, for example, textile machines, plastic machines as well as forming and bending machines.

Optimized Three-Phase Current Asynchronous Motors: Baumüller will be presenting the optimized series of three-phase current, asynchronous motors DA1-100-280 at the trade fair. The company is thus continuing the modular strategy for the main drive, thereby continuing to merge the DA1 series with the series of synchronous motors DS2. Among other things, an optimized water cooling in the sizes 100/132/160, similar to the DS2-100-160, IE3 fan motors according to the new IE directives for the air cooled motors as well as an optimized connection technology are new with the three phase current asynchronous motor.

Flexible Multi-Axis Controller b maXX 5800: At SPS, Baumüller will be exhibiting the flexible and compact multi-axis controller b maXX 5800. The controller for up to six drive axes can be configured individually and fully flexibly. This means that users can freely combine axis powers in the controller. The user can thus integrate exactly the right axis performance for each individual axis, resulting in a device that meets exactly the requirements of the user’s application.

High-Performance Compact Drive b maXX 2500: The high-performance compact drive b maXX 2500 with integrated electronics can be used regardless of the industry and therefore for numerous industrial applications, such as for robotics and handling applications. The decentralized servo drive reduces the wiring and installation costs, allows an optimal installation space, offers a high level of flexibility and is available in three sizes.

SPS IPC Drives, Nuremberg

November 27-29, 2018

Hall 1, stand 560