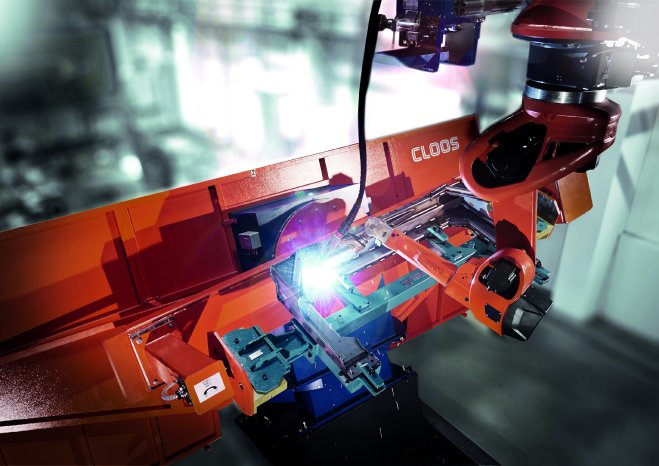

The DSH1 high precision servo motors were developed specifically for applications with the highest standards for quality and smooth operation. Typical areas of application, e.g. in the handling and robot field, include welding robots that produce components with a precise and high-quality welding seam. Due to the excellent control properties of the new servo motors, they are also ideal for label printing machines that have to achieve a consistently high and reproducible print quality.

The new motors can be optimally integrated into the current DS servo motor product range. With the existing modular system, the mechanical interfaces and connection technology are designed analogous to the existing Baumüller servo motors in the DSH1 series as well. This means that depending on the application requirements, the optimal servo motor can be used without requiring the machine manufacturer to make adjustments in the mechanics or connection technology. The maximum rotational speed range of the DSH1 servo motors, which are available in the sizes 45-100, is up to 6000 1/min with rated outputs of up to 10 kW in the self-cooling version.

Baumüller offers the right solution for every industry and application with its broad range of servo motors. Offering a selection of the motor series DSC1, DSD2, DSH1, DSP1 as well as the DSE-integrated motors, tasks in the handling and robotics area as well as special tasks in plastics, printing, textile, tool and packaging machines and many other areas can always be achieved with the precisely required performance.