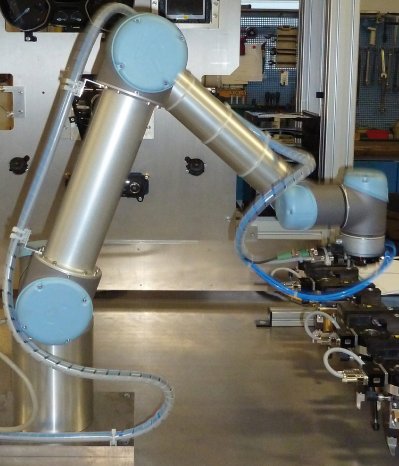

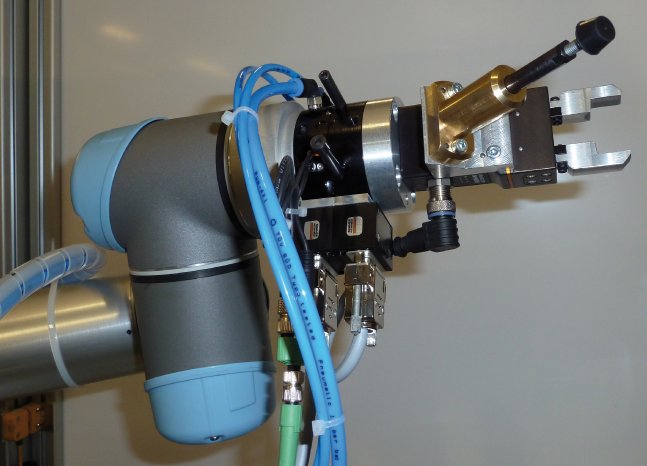

Where once car stereos or climate control were located, now head units of multi-functional infotainment systems can be found. The variety of infotainment functions has to be verified for different implementations. MESSINA RS executes the test sequences through precise control of a six-axis robotic arm enabling to run tests fully automated day and night. This allows for a greater testing depth in shorter time periods. The robotic arm precisely replicates the driver's operation therewith enabling automated testing of new and future operating concepts - such as touch screens, push rotary actuators or the changing of CDs.

Unique architecture and interface

MESSINA RS is based on the proven concept of the testing platform MESSINA. Model-based test specifications are stored in Rhapsody or Enterprise Architect as a sequence. They are imported into MESSINA and automatically converted into the required test codes. The parameters for the test sequence execution can be specified individually. The automatic tool change also allows for different test sequences to run automatically during the night or over the weekend. The MESSINA real-time HiL technology synchronously captures robot actions and all ECU signals relevant for test evaluation. The signals range from voltage and current values to CAN or LIN bus system signals. Open interfaces of the MESSINA RS system facilitate the integration into the customer's existing tool environments.

More information and a video showing MESSINA RS in live use can be downloaded at www.berner-mattner.com/....