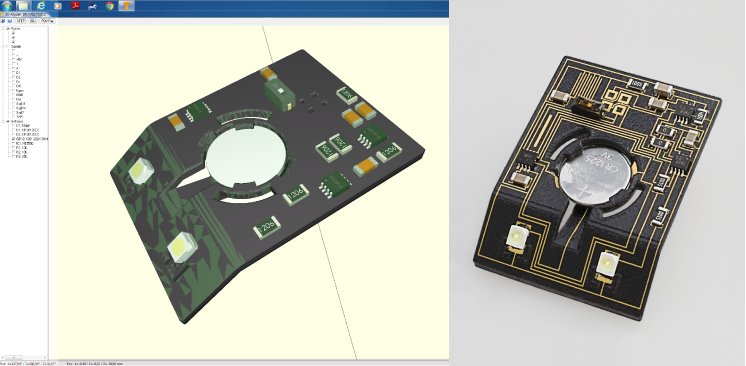

A highlight of Beta LAYOUT’s trade fair presence is their single-source prototyping and small-series manufacturing of 3D Mechatronic Interconnect Devices (MIDs). The circuit carriers of the three-dimensional circuit boards are produced at Beta LAYOUT using 3D printing. This eliminates the need for costly injection moulding dies, as commonly used in series production. After this, the MID components are processed on a special production line at Beta LAYOUT using laser direct structuring, and then assembled if so desired. These technologies make 3D MID-prototypes economically feasible even for companies with small production volumes. If the parts need to be produced in larger volume at a later date, Beta LAYOUT also offers a solution with the aid of their specialised partners.

Beta LAYOUT is also exhibiting a matching 3D MID CAD program, which will be available on the Beta LAYOUT website after the trade fair for free download as part of the TARGET 3001! PCB POOL® version. It enables developers to design and lay out 3D MID components themselves.

Beta LAYOUT is additionally exhibiting an innovation for their Magic PCB® technology, which allows RFID modules to be embedded in printed circuit boards for reliable, durable and fraud-proof identification of printed circuit boards and electronic devices. For reading RFID chips over WLAN, Beta LAYOUT has developed a low-cost UHF reader based on the Raspberry Pi computer module.