The machinery market shows worldwide an extremely high level of competition. Companies which succeed therefore have to meet the severe preconditions such as shorter commissioning of plant and machinery, lower engineering costs as well as a continuous optimization of plants and processes. Moreover an efficient global service network is also decisive for a competitive position in the markets. According to market analysts companies in this regard can only fulfil these requirements by CAD data based virtualization of machines and by using 3D technologies. Thus virtual reality enables to test and optimize different functions of the plants and machines before they will be really engineered.

The 3D real time visualization allows both a realistic rendering of different functions in a testing mode and the cooperation of engineers for planning, construction and automation. By using this mutual describing tool the engineers can implement technical modifications or new installations very fast. In addition to that the user avoids downtimes of the machines and plants and saves therefore remarkable expenses.

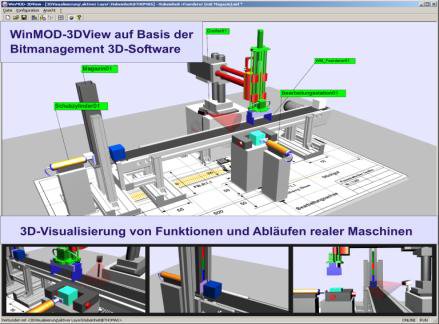

Mewes & Partner, Henningsdorf, Germany a machinery CAD data based solution provider offers a platform (WinMOD) for virtual commissioning of plants, for planning, training, service and education in the automation engineering area. As a software partner Bitmanagement Software GmbH contributes its 3D viewer technology (BS Contact) which is implemented in the three real time simulation systems from Mewes & Partner. The 3D software from Bitmanagement meets all requirements such as interactivity, highest rendering performance and the ability to run on standard personal computer or laptop/notebook.

More information: Virtual Realtiy Magazin 03/2010

http://www.virtual-reality-magazin.de/...