For the past 90 years, BITZER has remained committed to its vision of shaping the future with its customers and partners, which is why ‘SHAPING THE FUTURE WITH YOU’ has been the BITZER motto during the anniversary year. What does this motto mean to the long-standing company? ‘Together we can pursue the vision of a better future for the refrigeration, air conditioning and heat pump industry as well as for the environment and society. That is our central aim. And we are working hand in hand with our customers and partners,’ says Martin Büchsel, Chief Sales and Marketing Officer at BITZER. ‘And we are ready to do it – thanks to our nine decades of expertise and our energy-efficient, smart products for the refrigerants of the future.’

A look back at the company’s history reveals that BITZER has long had its sights set on the future. Since it was founded by Martin Bitzer in 1934, the company has developed from a small workshop in the Swabian town of Sindelfingen, Germany, to a global company now with 75 locations in 40 countries.

The company’s origins with Martin Bitzer and Ulrich Schaufler at the helm

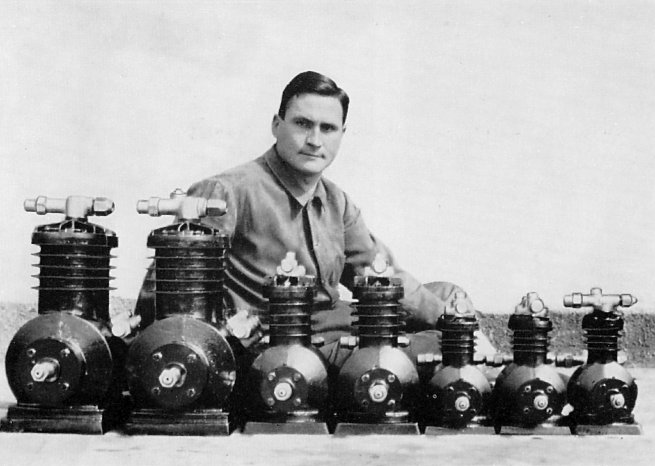

Martin Bitzer started out manufacturing thermostatic expansion valves from steel – an innovation in Germany at that time. But production expanded quickly, and refrigeration compressors were soon the company’s core business. The first BITZER compressors were reciprocating compressors with co-current flow design, with which the company achieved its first international successes in the 1930s – in Argentina. BITZER developed the open drive 2-cylinder reciprocating compressors in 1940 – initially types I to IV and then types V to VII – thus laying the foundation for the real open drive compressors. The company continued to develop new technologies at lightning speed in the 1950s – beginning with the production of shell and tube condensers and liquid receivers for in-house unit production, and culminating in the groundbreaking arrival of the age of motor compressors. Introducing the BITZER Hermeta (BH) series was the first step in 1954. These hermetic compressors with welded or cast housings featured drive power of up to 0.75 kW and were designed for use with R12 and R22. These two refrigerants were also used with BHS semi-hermetic compressors with drive power of up to 10 kW, which were manufactured from 1959 and 1960. The young company was so successful that the site had to be expanded five times between 1938 and 1958. The number of employees increased from 26 in 1946 to 212 in 1960, which is more than eight times as many.

In 1961, Martin Bitzer passed the company down to engineer Ulrich Schaufler. After taking over, the new company owner relocated a portion of production to the new factory in Eschenbrünnlestrasse in Sindelfingen. In 1972, BITZER expanded its series of semi-hermetic reciprocating compressors to include larger 4- and 6-cylinder models with drive power of up to 30 kW, designed for use with the R12, R22 and R502 refrigerants. These new compressors were the most modern of their time, representing a giant step forward into the future.

Peter Schaufler: a focus on expansion and innovation

In 1979, Ulrich Schaufler’s son, Senator h. c. Peter Schaufler, took over the company, which at that time had 270 employees. In the 1970s, BITZER began developing compressors for natural refrigerants with low global warming potential like ammonia (R717), CO2 (R744) and propane (R290). The specialist in refrigeration, air conditioning and heat pump technology has been continuously optimising its components ever since and now offers the right technology for any application and just about any refrigerant – with a focus on maximum energy efficiency, especially when it comes to legal requirements like the Ecodesign Directive and the F-Gas Regulation. This allows the company to respond to the growing demand of its customers and partners resulting from rising energy prices, a growing number of applicable regulations worldwide and greater environmental awareness. For example, BITZER is the only manufacturer to include reciprocating, screw and scroll compressors with propane in its portfolio.

The market launch of semi-hermetic and open drive screw compressors with a capacity lower than that of the established product range was nothing short of revolutionary in 1983. Screw compressors were considered to be the pinnacle of compressor production in the industry at that time. Soon after they were launched, the compressors were fitted with an economiser connection and integrated capacity control as standard. Initial testing with frequency inverters for speed control kicked off in 1984, and a chiller was equipped with this innovative technology two years later, ensuring a whole new level of efficiency in the part load range. With the ‘second generation’, BITZER achieved yet another milestone in 1986 on its journey to becoming a European market leader in semi-hermetic reciprocating compressors. They improved energy efficiency significantly, expanded the range of applications and offered maximum reliability. At the same time, the company introduced the selection software, a wholly innovative, practical tool, which has since established itself in the market and is now known in the industry as BITZER SOFTWARE. Launched in 1992, the BITZER Refrigerant Report bundles all relevant information about refrigerants and is now available exclusively in digital form.

With the development of the EuroScroll scroll compressors in 1996 and their market launch, BITZER was the only company to offer all three primary compressor technologies: reciprocating compressors, screw compressors and scroll compressors. Development of the CSH75 compact screw compressors was yet another huge success that ultimately changed the refrigeration industry in 1999. Additional successful models followed in the coming years, including the ECOSTAR condensing units in 2007, the ORBIT 8 scroll compressors in 2008 and intelligent CSV screw compressors with integrated, refrigerant-cooled frequency inverter from 2012, all of which enabled an incomparable control range and seasonal energy efficiency. Production of ECOLINE reciprocating compressors kicked off in 2013 and was followed a short time later by the launch of an independent ECOLINE CO2 range.

Until his death in 2015, Senator h. c. Peter Schaufler operated the company consistently with an international focus for all those decades. Under his leadership, the company based in Germany’s Swabian region developed into a global player and a driver of innovation for the entire refrigeration and air conditioning sector. With 3400 employees in more than 90 countries and turnover of 657 million euros, BITZER had more than twelve times the staff in 2015 than it did when Senator h. c. Peter Schaufler took the helm. His decisions were shaped by entrepreneurial courage. For example, he founded a joint venture with a Chinese company in Beijing back in 1994. Senator h. c. Peter Schaufler was highly committed to the common good throughout his life. In 2005, he founded

THE SCHAUFLER FOUNDATION with the aim of bringing together entrepreneurship, science, research and art – for example, with endowed chairs at different universities. Senator h. c. Peter Schaufler and his wife Christiane Schaufler-Münch also supported social institutions and in 2010 made around 3500 pieces of their extensive private collection of contemporary art available to the general public at SCHAUWERK Sindelfingen.

A new era after Peter Schaufler

To this day, Christiane Schaufler-Münch continues to manage the company with four board members. Named after the company owner of many years, Senator h. c. Peter Schaufler, the SCHAUFLER Academy opened its doors in 2016 as the international BITZER training centre located at the Rottenburg-Ergenzingen site in Germany. The institution has also played a key role in ensuring proper use of groundbreaking refrigeration, air conditioning and heat pump technology ever since. With the growing complexity of components and systems such as integrated frequency inverters, electronic components and the use of natural refrigerants, well-founded seminars and training courses are an absolute must in the industry.

Digital tools and applications, including various software programs and apps, have been standard components at BITZER for years now. With its digital products and services, BITZER is pursuing the single aim of simplifying work for its customers and partners, who can use the free SPOT app, for example, to verify the authenticity of BITZER products. Additionally, the app provides them with extensive documentation and a directory of all BITZER and Green Point locations as well as all certified dealers. The BITZER Green Point service and maintenance network was launched in 2006 and boasts a global presence. The company portfolio of energy-efficient and intelligent electronic components for the refrigeration, air conditioning and heat pump industry has grown consistently in response to the increasing expansion of digital products and services in recent years. For example, the IQ MODULE CM-RC-02 simplifies and optimises compressor installation, operation, maintenance and retrofitting for refrigeration, air conditioning and heat pump systems.

BITZER structures its processes on a foundation of sustainable technologies and resources, all in an effort to continue shaping the future of the industry in a meaningful way and building on the last nine decades. For BITZER as an international company, sustainability is a global task anchored not only in products and processes, but also in other dimensions of the company’s DNA, including investments, supply chains and social spheres. For example, the specialist in refrigeration, air conditioning and heat pump technology is working towards offsetting all carbon emissions at its German locations in Sindelfingen, Rottenburg-Ergenzingen and Rottenburg-Hailfingen by 2030, relying on a mix of different types of energy such as photovoltaics.

SHAPING THE FUTURE WITH YOU: #morethanacompressor and #greencompetence

The company’s origins are important to BITZER. But working with its customers, partners and employees to shape their future is even more important to the company. The specialist in refrigeration, air conditioning and heat pump technology represents #morethanacompressor. In addition to compressors, the company’s portfolio also includes components that allow compressors to operate even more efficiently, with a core focus on energy efficiency. After all, energy consumption accounts for a majority of the product’s carbon footprint throughout its life cycle. The company also represents #greencompetence. BITZER is committed to sharing its knowledge and expertise. In fact, personal advice, exchange with customers and partners, seminars and training courses are a top priority for the company.

The 90th anniversary is a milestone that underlines the company’s many years of tradition and focus on the future. You can look forward to watching the driver of innovation in the refrigeration, air conditioning and heat pump industry write its story over the decades to come – with the support of its employees, customers and partners. Keep up to date on the latest information about the company:

// BITZER website: https://www.bitzer.de/gb/en/

// BITZER on social media:

- LinkedIn: https://www.linkedin.com/company/bitzer/

- Facebook: https://www.facebook.com/BITZERGroup/

- XING: https://www.xing.com/pages/bitzer

- YouTube: https://www.youtube.com/@BITZERGroup